Month: June 2016

Heat Sealers

Helpful Tips | Heat Sealer Trouble Shooting

Product Info: Vacuum Packaging

Product Info: Wholesale Plastic Bags

Product Info: Vacuum Pack Bags

Fact Sheet: Venus Vacuum Sealers

Why vacuum pack?

Exposure to air aids the growth of bacteria in most foods. Sealing the food in a bag from which the air has been removed greatly inhibits bacterial growth. Foods stay fresh longer and retain their flavour, nutritional value and sales appeal.

Which foods can be vacuum packed?

Any food can be vacuum packed but the unique characteristics of each food must be considered. For example a high vacuum sealer might crush delicate foods such as berries. See “Vacuum sealing tips.” (Below).

How long do vacuum packed foods last?

Some foods will last up to 5 times longer than without vacuum packing. But it depends on the type of food and its quality before packing. It is important to remember that foods that normally need to be kept cool to prevent spoilage still need to be refrigerated or frozen as usual.

Vacuum sealing tips

- Freeze liquids such as soups and delicate foods such as berries before vacuum sealing.

- Avoid overfilling. For bags leave 7cm space above contents, for canisters leave 2.5cm.

- For powdery foods place a coffee filter or folded paper towel in the bag below the seal area.

Making Bags

Unroll the desired length.

Cut off with sliding cutter.

Place open end on seal bar.

Close lid. Lock down. Press “Seal Only” button.

Sealing Bags

Place open end of filled bag below air outlet.

Close lid. Lock down. Set desired seal time.

Press “Vacuum Seal” button. Vacuum light comes on.

When vacuum light goes out, release lid.

Sealing Canisters

Attach connector to canister port.

Place connector cap over centre of canister lid.

Press ‘Canister Only’ button. Canister light comes on.

When canister light goes out, release lid.

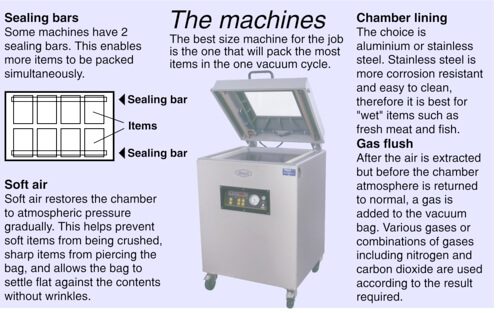

Fact Sheet: Venus Vacuum Chambers

Why vacuum pack?

Exposure to air aids the growth of bacteria in most foods. Sealing the food in a bag from which the air has been removed greatly inhibits bacterial growth. Foods stay fresh longer and retain their flavour, nutritional value and sales appeal.

Which foods can be vacuum packed?

Any food can be vacuum packed but the unique characteristics of each food must be considered: for example delicate foods such as berries might be crushed by a high vacuuum. This is often overcome by freezing the berries first or using gas. See Why Use Gas? (right). T-bone steaks might pierce the vacuum bag. See “Soft Air” (below).

How long do vacuum packed foods last?

Some foods will last up to 5 times longer than without vacuum packing. But it depends on the type of food and its quality before packing. It also depends on the type of barrier bag used and the strength of the seal. It is important to remember that foods that normally need to be kept cool to prevent spoilage still need to be refrigerated or frozen as usual.

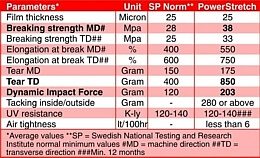

Which Is The Toughest Silage Film?

Silage film has to cope with some pretty rough treatment. While its main purpose is to provide optimum fermentation by keeping the air, light and water out, first it has to survive wrapping, handling and stacking.

Wrapping silage film with PowerStretch during product testing in Gippsland, Victoria.

If it fails that test whatever other qualities it has mean very little. So toughness – resistance to puncture, tearing and breaking; and correct tackiness to ensure a strong air-tight seal have to be the main considerations.

That’s why when evaluating products to replace our earlier generations of silage films we put toughness, tackiness and UV resistance at the top of the check list and PowerStretch was the easy winner.

When it comes to its tear resistance (transverse direction) PowerStretch is more than twice as tough as the Swedish National Testing Institute minimum standard. And its capacity to withstand dynamic impact force – that is, its puncture resistance – is 70% higher than standard films as illustrated in the chart below.

Breaking strength is higher too, in fact 35% higher than standard films and tackiness is carefully controlled during manufacture to ensure instant adhesion and a strong air-tight seal with minimal tails.

High puncture resistance means minimum risk from hard, stiff crops.

More than twice the tear resistance means minimum risk of breaks on high speed balers due to abrupt starts or stress at the corners of square bales. 70% higher puncture resistance minimises the risk of perforations from hard stiff crops and damage during handling, stacking and storage. And 35% higher breaking strength guarantees optimum performance throughout every roll. No down-time getting out of the tractor to re-attach broken film means more bales wrapped per hour, increased output and therefore profit.

PowerStretch owes its toughness to its uniform thickness made possible by the latest multi-layer construction techniques and highest quality octene polymers. This also gives it excellent uniform opacity.

The final result is a tough, compact bale that is highly impermeable to light, air and water for optimal fermentation.

PowerStretch is UV stabilised for 12 months and available in 5 layer green and 3 layer black. Both are 25 microns thick in rolls 750mm wide by 1500 metres.

For more information speak to Venus baling products specialists, Phil Pomeroy or Wayne Shearer on (03) 9428 1652.

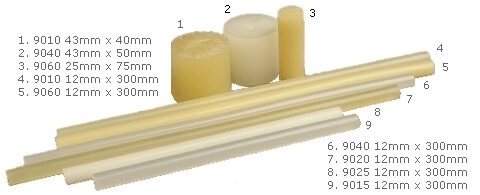

Everything You Wanted To Know…

Venus Hot Melt Glues are made from 100% solid adhesive. Because they are not solvent based they are friendly to the environment and will not taint foods or other packaged items. Also because they are solvent and water free there is no wastage and no glue odours when set. Venus Hot Melt Glues have an almost unlimited shelf life and are far easier to use and store than messy cans and tubes.

Hot Melt Formulation

All Venus Hot Melt Glues are composed of a basic POLYMER such as EVA (ethyl vinyl alcohol), PP, ethylene or poyamide mixed with a natural or oil derived TACKIFIER resin which holds the elements together and also determines the adhesive strength. A high tackifier content gives lower viscosity and a stronger bond. RESIN gives the adhesive its tackiness. Paraffin or polythene WAX is used as a viscosity modifier: a higher wax content produces faster setting and a crisper bond.

Other ingredients include ANTI- OXIDENTS to stabilise the colour, RUBBER to increase resilience and reduce brittleness, PLASTICISERS and OILS to extend the open time. Where substrates might be exposed to temperature extremes and where impact resistance is required at low temperatures it is necessary to consider the more expensive polyamide glues such as Venus 9901.

Hot Melt Terminology

Viscosity is the liquidity of the adhesive in its hot state and is generally quoted in centipoise (CPS) at a given temperature. The lower the CPS value the thinner the liquid. Water has a value of 1 CPS. Viscosity is quoted in a fairly wide range (ie 7000 to 10000 CPS) as chemical companies only manufacture to a +-2% variation on softening point specification. Therefore viscosity varies from batch to batch.

Open Time is the maximum working time before the adhesive cools to a point at which only marginal bonding can take place. It is based on adhesive formulation and rate of heat loss. Temperature Resistance is the resistance of the bond to heat and cold. Important to electronic component assembly, deep freeze packaging etc. The Venus range of EVA polymer glues includes temperature resistances from -20°C to +80°C and polyamides from -20°C to + 149°C.

For more information speak to Venus Packaging on (03) 9428 1652. For a detailed description of each Venus Hotmelt Glue download the Venus Carton Sealing Guide.

Netwrap: How Many Wraps Is Enough?

The cost of the netwrap to make a round bale is a very small percentage of the value of the hay, yet one of the main causes of collapsing bales is the failure to use enough netwrap.

Bale size, crop type, bale density and netwrap strength influence the correct number of wraps but some suppliers offer just one strength.

Venus Packaging say their Totalcover brand in 11, 12, 13, and 14gm per linear metre by 1.23 metre width enables farmers and contractors to choose the optimum combination of strength and wraps for any crop. For example the tensile strength of 13gm is 270kgf* and 14gm is 290kgf*. (*Approx.)

Netwrapped bales at Maffra Vic. Baled with a New Holland BR750 using 1.23m wide 12gm Totalcover.

The biggest factors that determine the wraps required are crop type and bale density. Crops like sorghum, triticale and pea that easily absorb moisture need more wraps, as do springy cereal crops. Heavy or abrasive crops such as rice straw and sugar cane need extra wraps and a heavier netwrap like 13 or 14gm.

Other considerations include how quickly the bales will be fed out: will they be stored in a shed, left in the paddock or sold? One extra wrap could greatly reduce the risk of bales splitting or breaking during loading, handling and transportation.

Farmers can prevent most problems by talking with their contractor about the best choice of netwrap, the correct weight for the job and how many wraps to apply.

Contractors are judged by the bales left behind in the paddock. The cost of more wraps or a heavier netwrap is negligible compared to the value of satisfied customers returning year after year.

For more information speak to Venus Packaging twine and netwrap specialist, Phil Pomeroy on 0427 684792 or (03) 9428 1652. Download Totalcover Netwrap product guides.

UPDATE JANUARY 2015

Since this article was written Totalcover tensile strengths have increased progressively. They are now: 11gm 270kgf, 12gm 290kgf, 13gm 310kgf and 14gm 330kgf.

Nine Tips For Better Big Square Baling

Now’s the time to make sure your baling equipment is in top condition.

With the baling season just weeks away it’s time to make sure your baling equipment is in top condition. “First, have a good look at your baler’s Manual for specific checks and adjustments,” says Danny Dahlitz, an expert with 40 years experience in the field.

Danny, who is the Senior Service Technician at Ramsey Bros. Saddleworth branch, suggests the following pre-season checks to avoid problems in the paddock with twine during the stress of the season.

Trevor Thompson (left) Luke Schwarz and Brad Abbott, Ramsey Bros. Saddleworth branch.

1. Check the twine tension.

2. Check the bill hook opening. The right measurement will give a perfect tail length.

3. Check the twine disk adjustment to reduce mis-ties.

4. Check the tension on top and bottom twine holding gears.

5. Check the condition of needle rollers.

6. Operator to set correct moisture content, bale load and density of crop to be baled. If settings are too high or low it will affect the load on the twine during the tying cycle.

7. Check the knife on the knotter arm is sharp.

8. Check the timing of knife arm to bill hook. This is most critical.

Danny’s ninth tip? “With big square bales it’s all about knot strength. So use a strong twine like Extra Blue at 245kgf.”

Ramsey Bros., now in their 60th year in the farm supplies business, operate 6 branches in SA employing sixty staff, 13 of them at the Saddleworth branch.

For more information speak to Ramsey’s twine and netwrap specialist, Trevor Thompson, on (08) 8847 4211 or Phil Pomeroy at Venus Packaging on (03) 9428 1652. Download the Venus Baler Twine Guide.