Back to blog

Back to blog

How a Pallet Wrapper Can Decrease Potential Health and Safety Issues

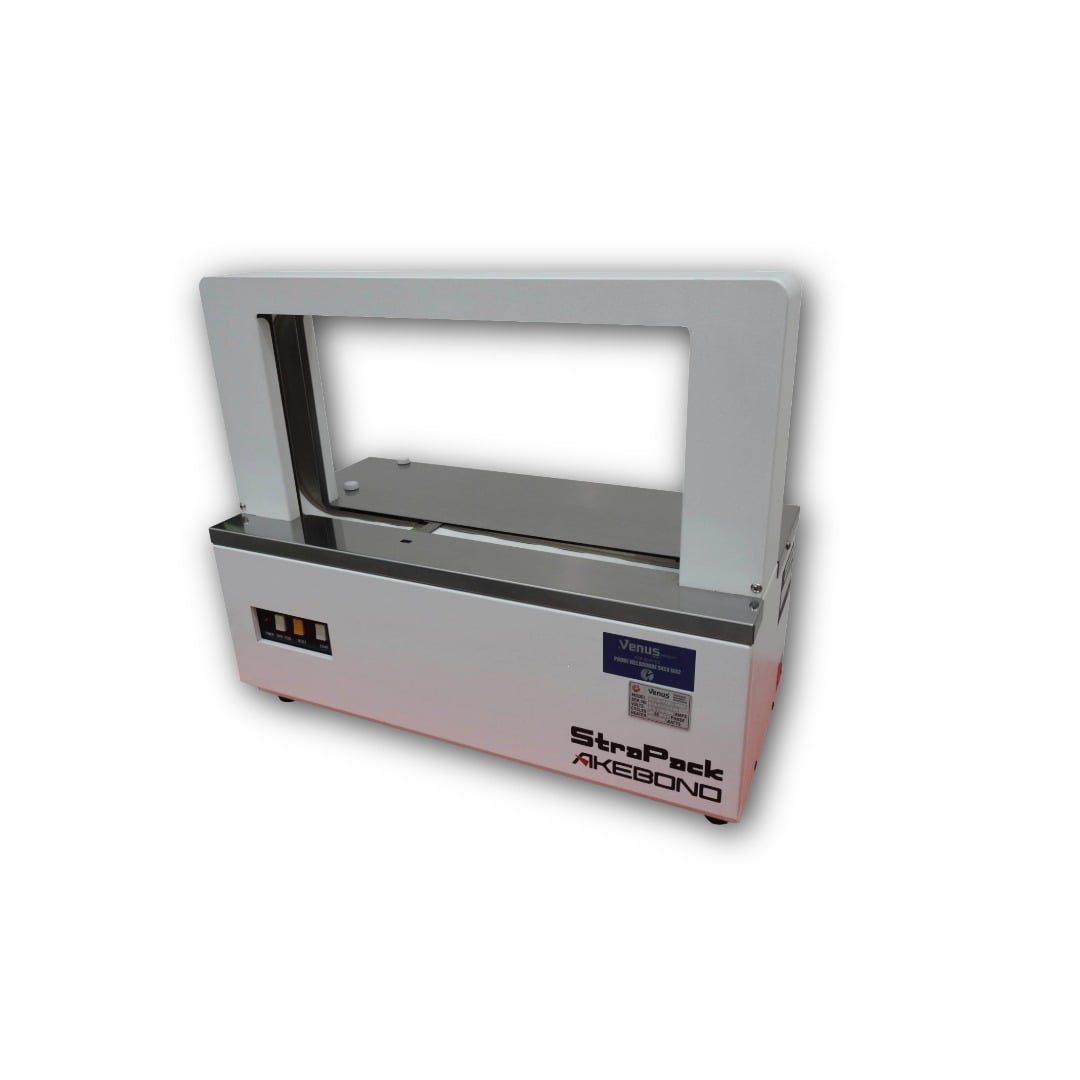

If your business is involved in the distribution of products around Australia or the world, you will probably at some point have considered the use of an automatic pallet wrapper.

Introducing a pallet wrapper into your dispatch operations has the following immediate benefits:

- The stability and high holding force that the stretch film creates offers a much safer wrapped pallet, which is far less likely to fall over and cause injury or road accidents during transit

- The application of the pallet film is undertaken by the pallet wrapping machine, hence significantly reducing the likelihood of sprains and strains of your staff members than if using manual wrapping techniques

- Goods securely wrapped and transported within warehouses on pallets reduce the likelihood of injuries through lifting individual items or cartons.

Further, the use of a pallet wrapping machine using stretch wrap offers more advantages, including:

- It’s the most cost effective method of keeping cartons together in one shipment

- The product, if using transparent pallet stretch film, is easily identifiable

- Shipments are protected from the elements, such as rain and sun, and product arrives in a protected, untampered state

- It can lead to highly efficient warehouse operations, as goods can be wrapped as soon as they are produced / picked and are ready to ship almost immediately; the average time to wrap a fully loaded pallet would be around 30 seconds

- From a marketing perspective, the wrapped product is professional looking and able to be branded

We have a fully trained service team based in Melbourne, Australia, who are available on the phone and in person to attend to any service query or maintenance issue you may have with your pallet wrapping machine.