Spare Parts Kits

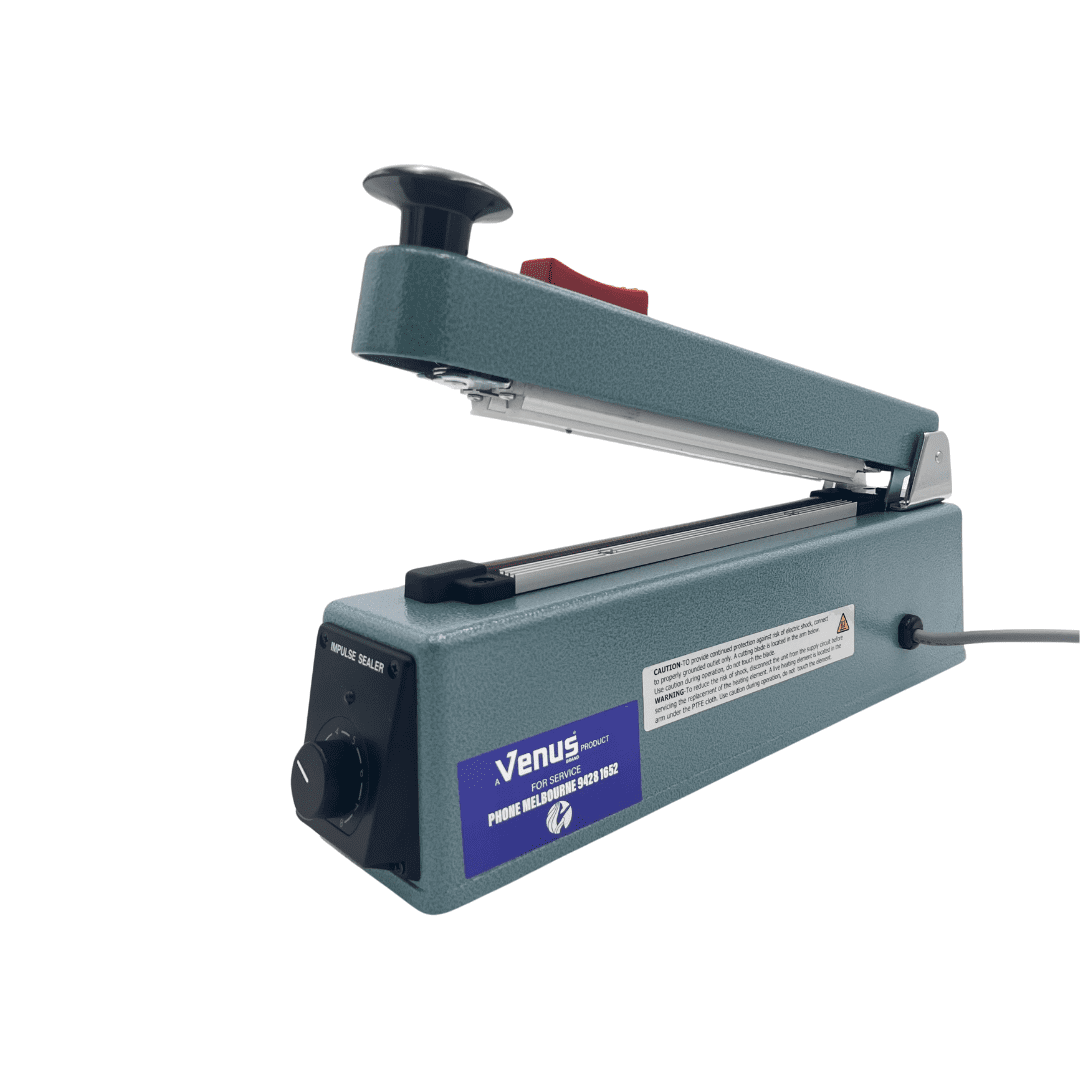

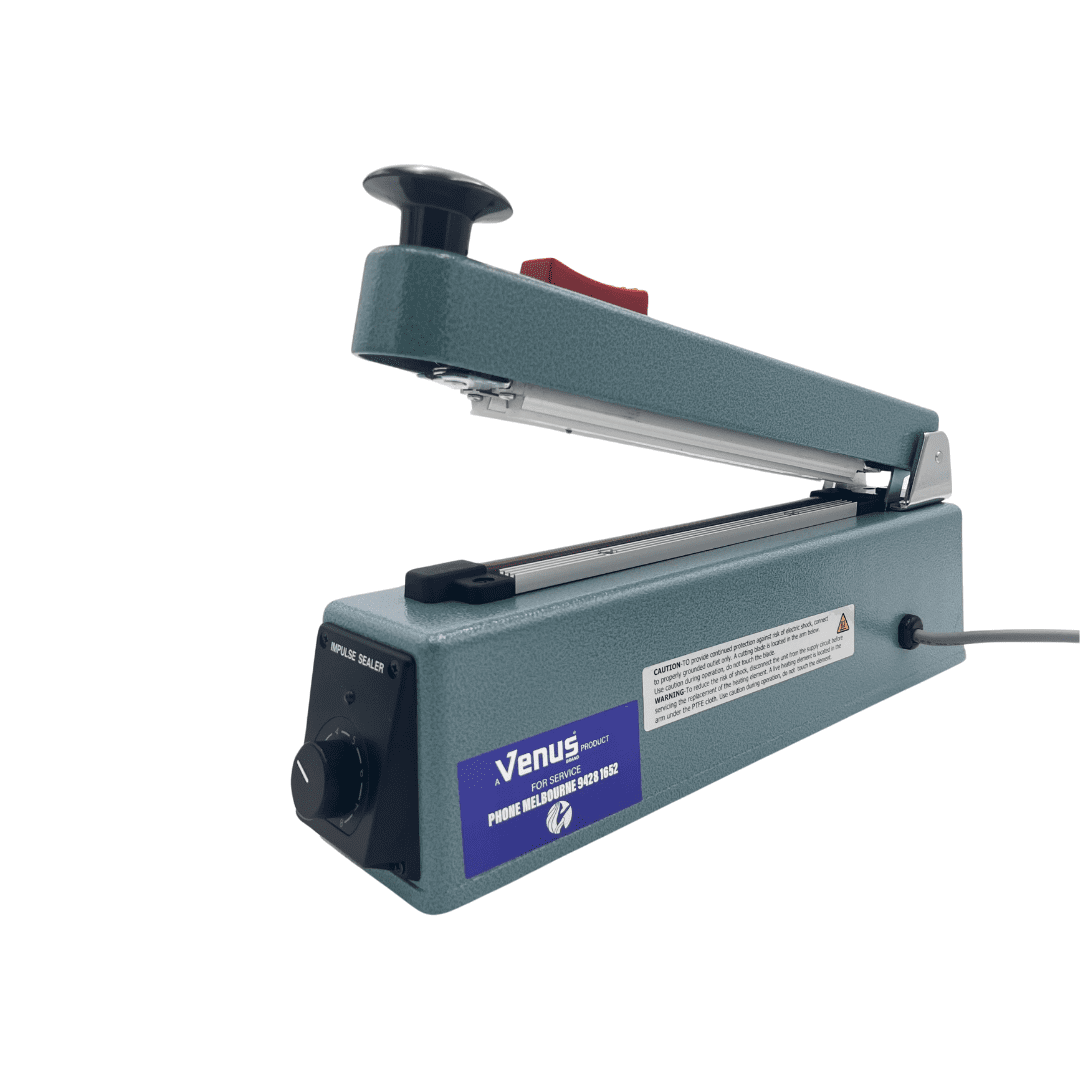

Benchtop Heat Sealers

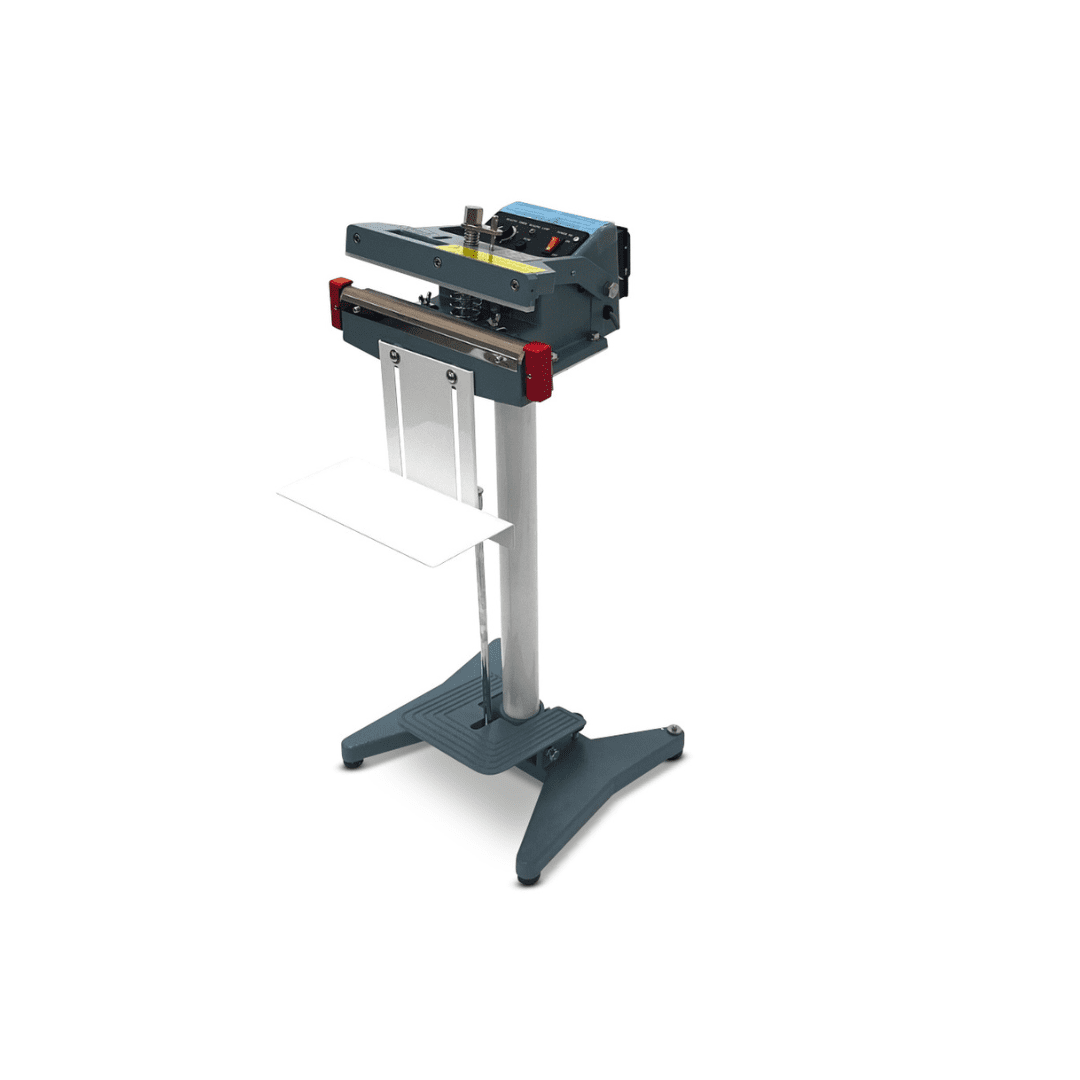

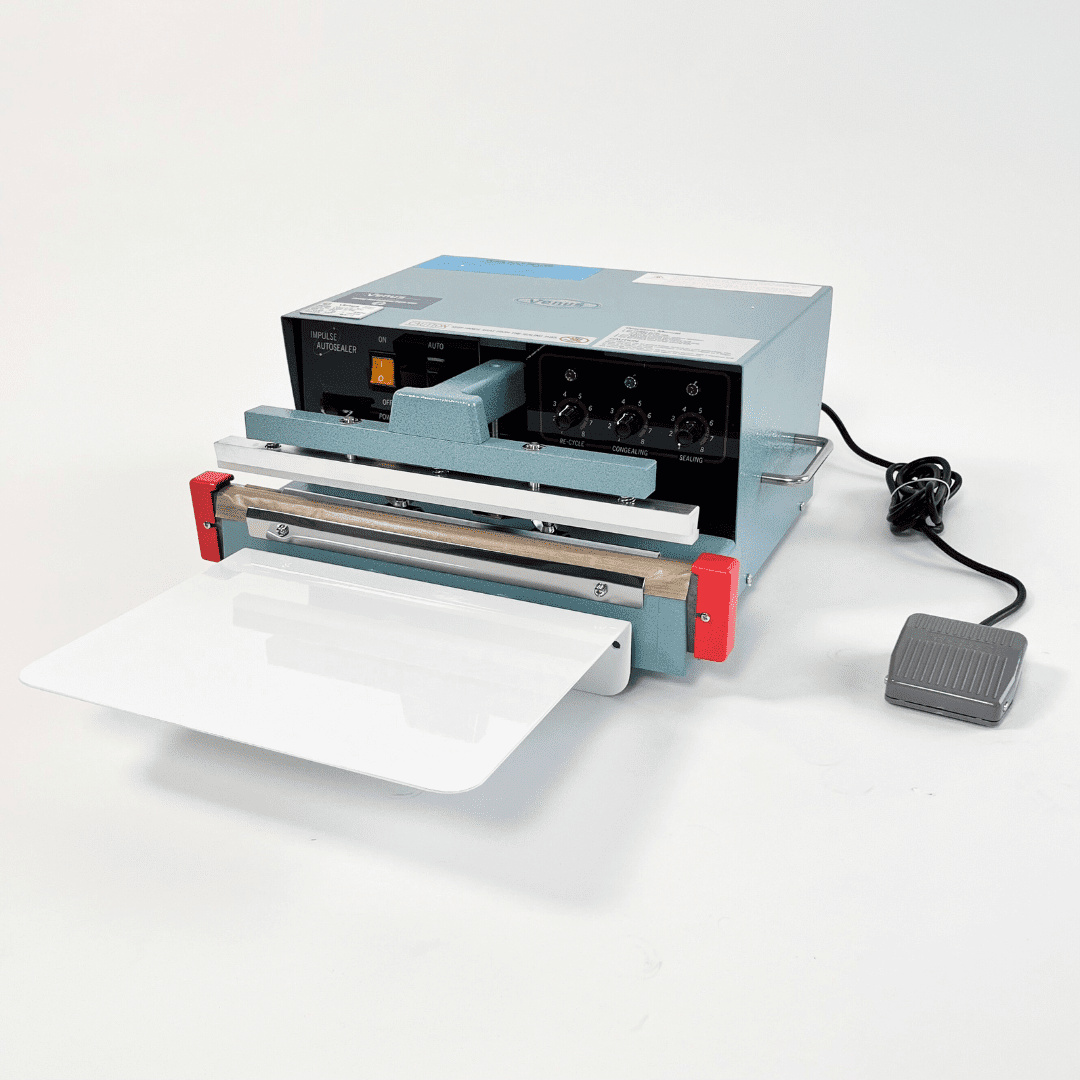

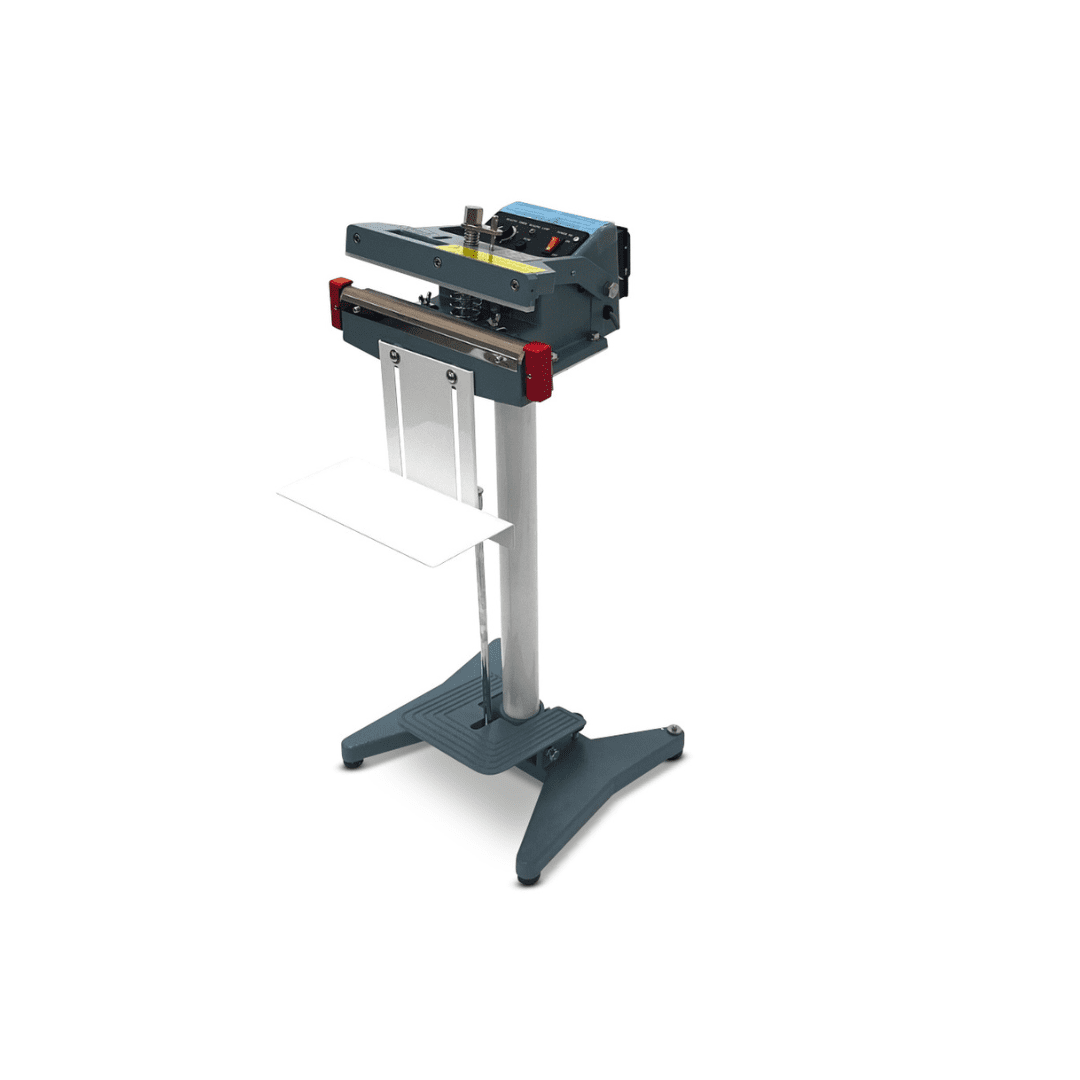

Foot Pedal Operated Impulse Heat Sealers

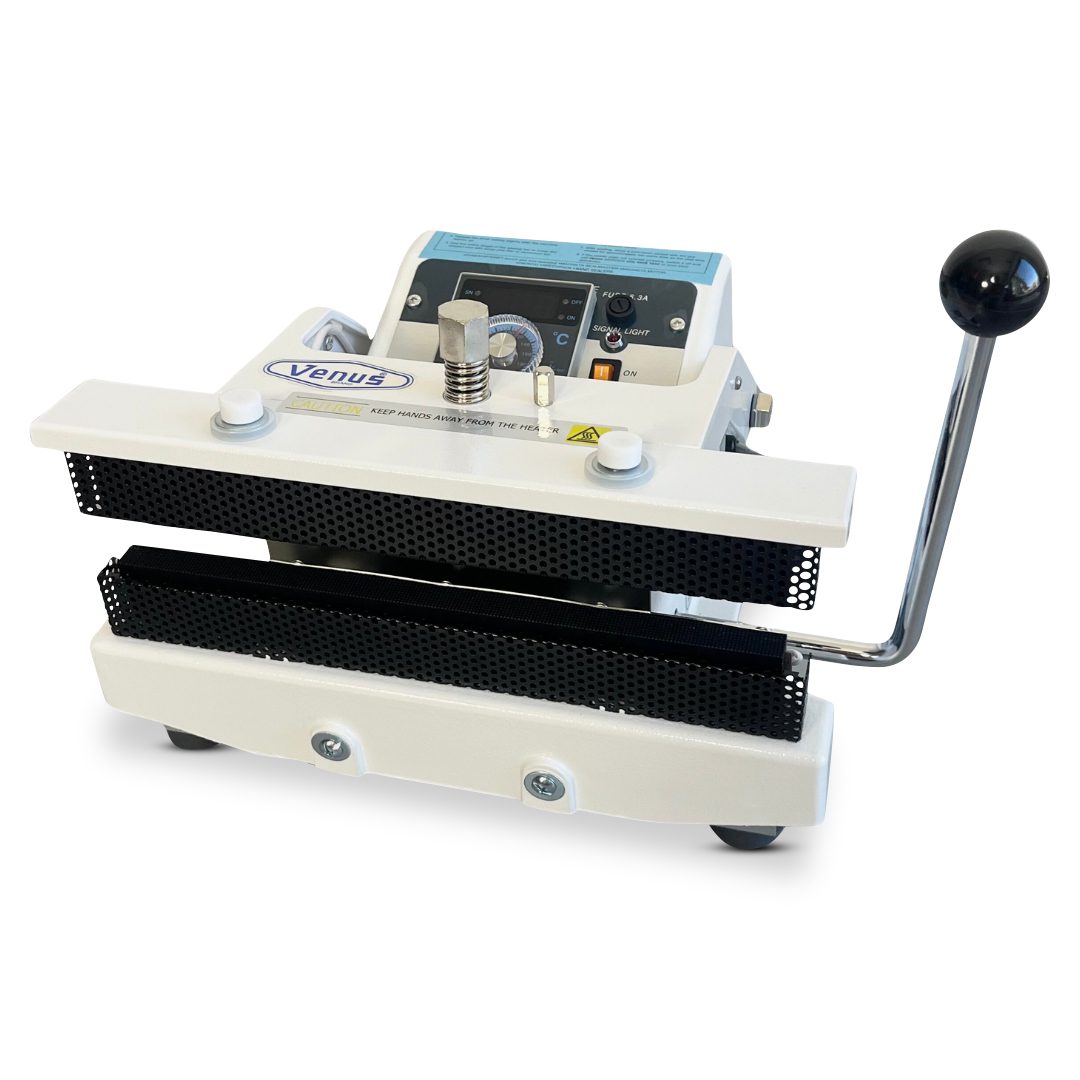

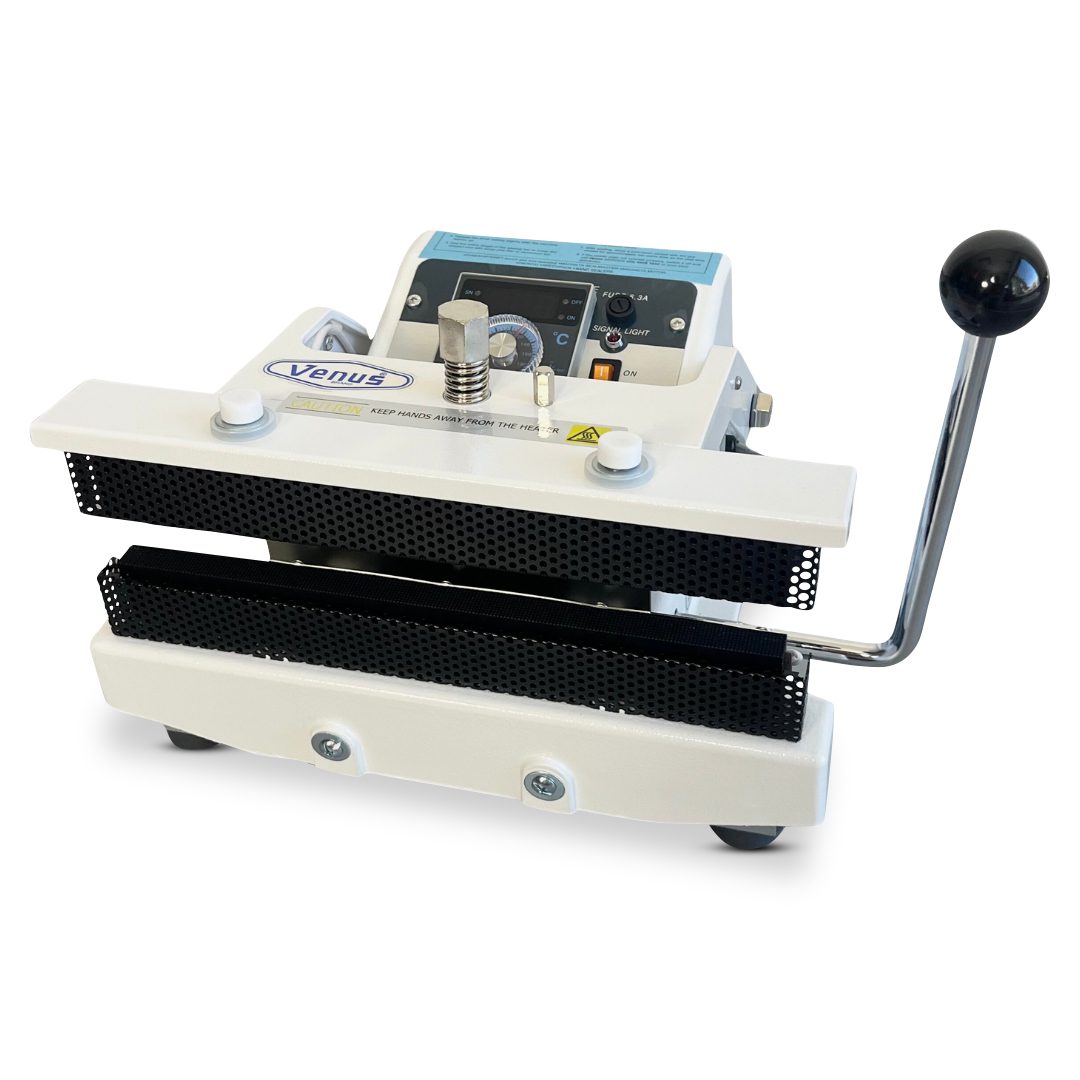

Constant Heat Sealers

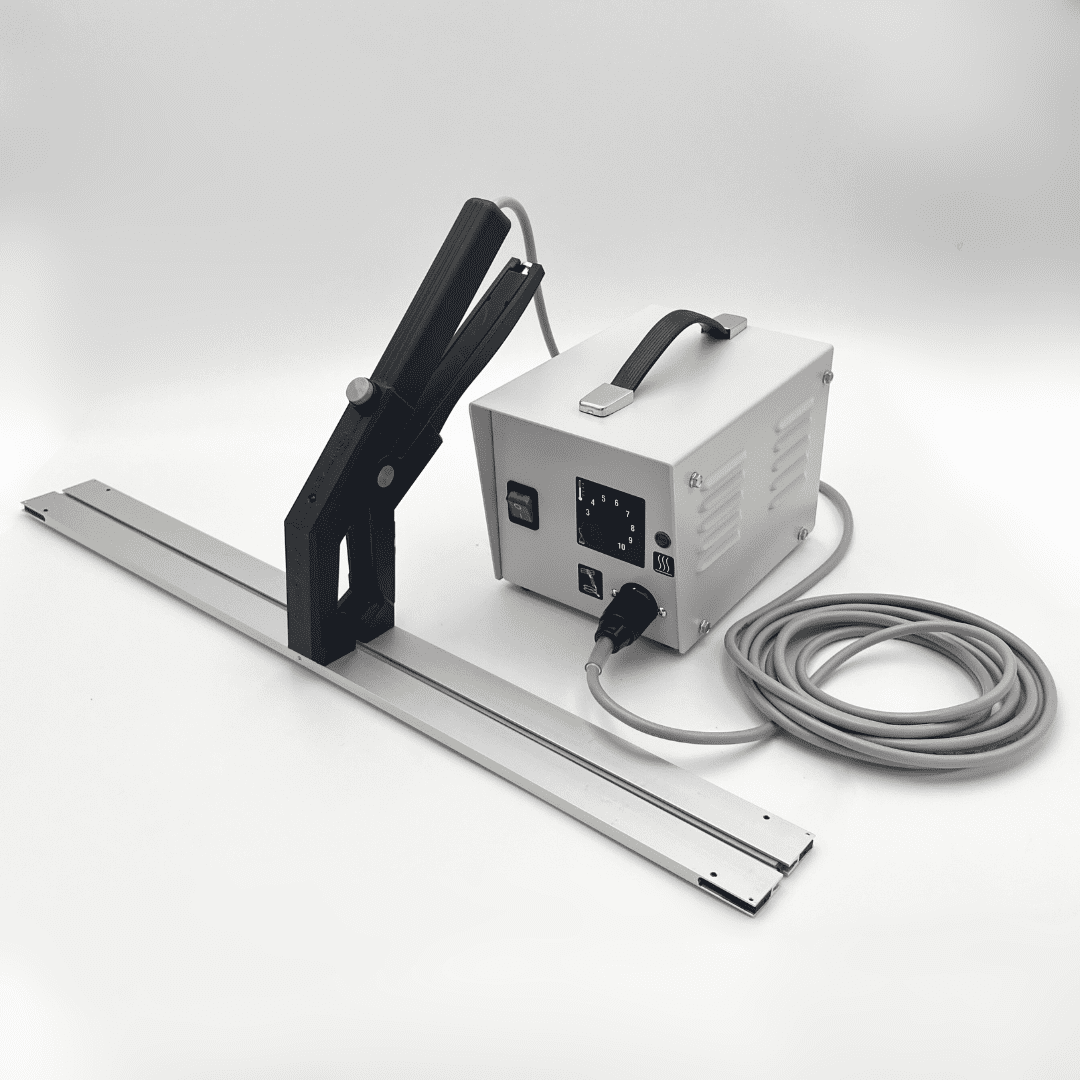

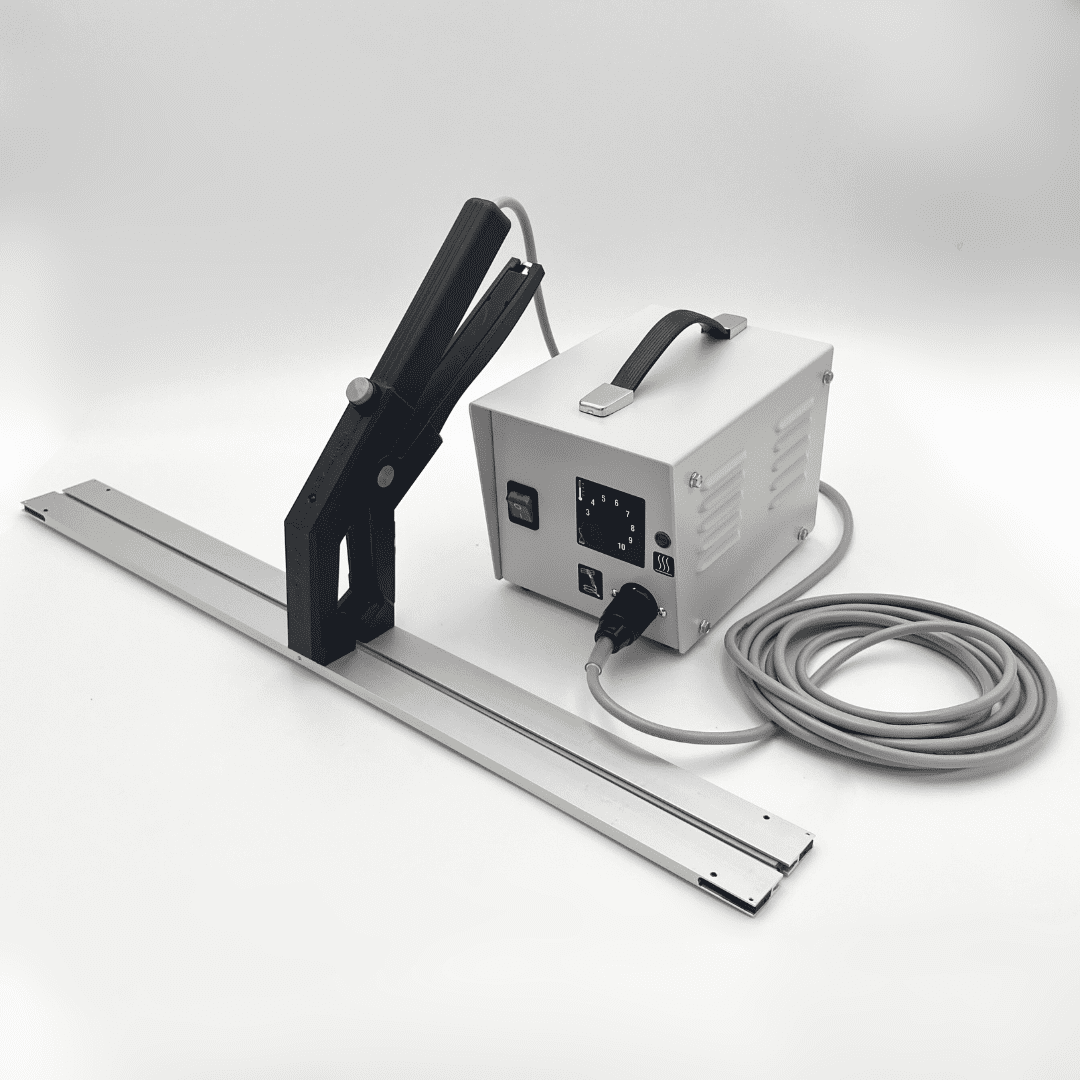

Hand Held Heat Sealers

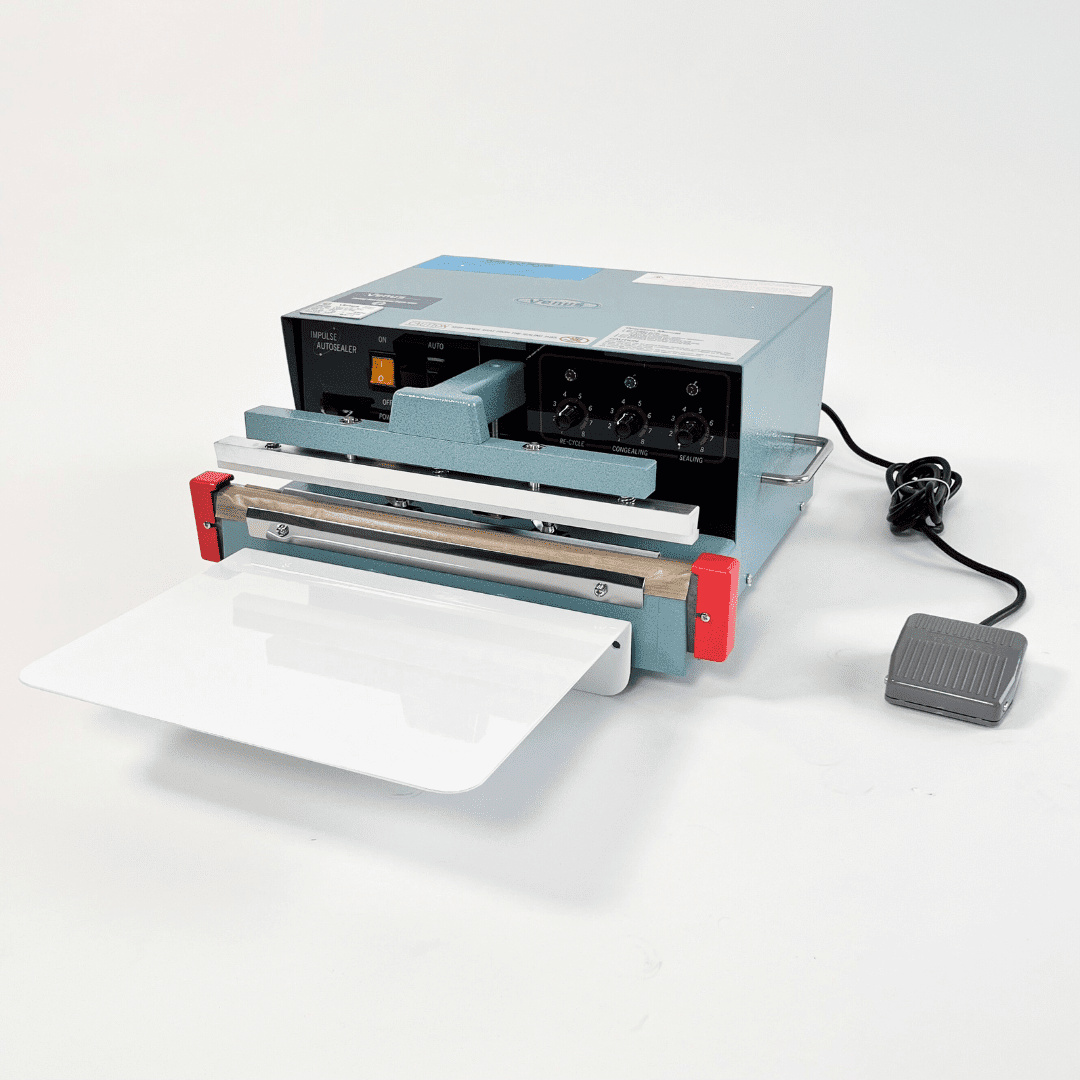

Automatic Heat Sealers

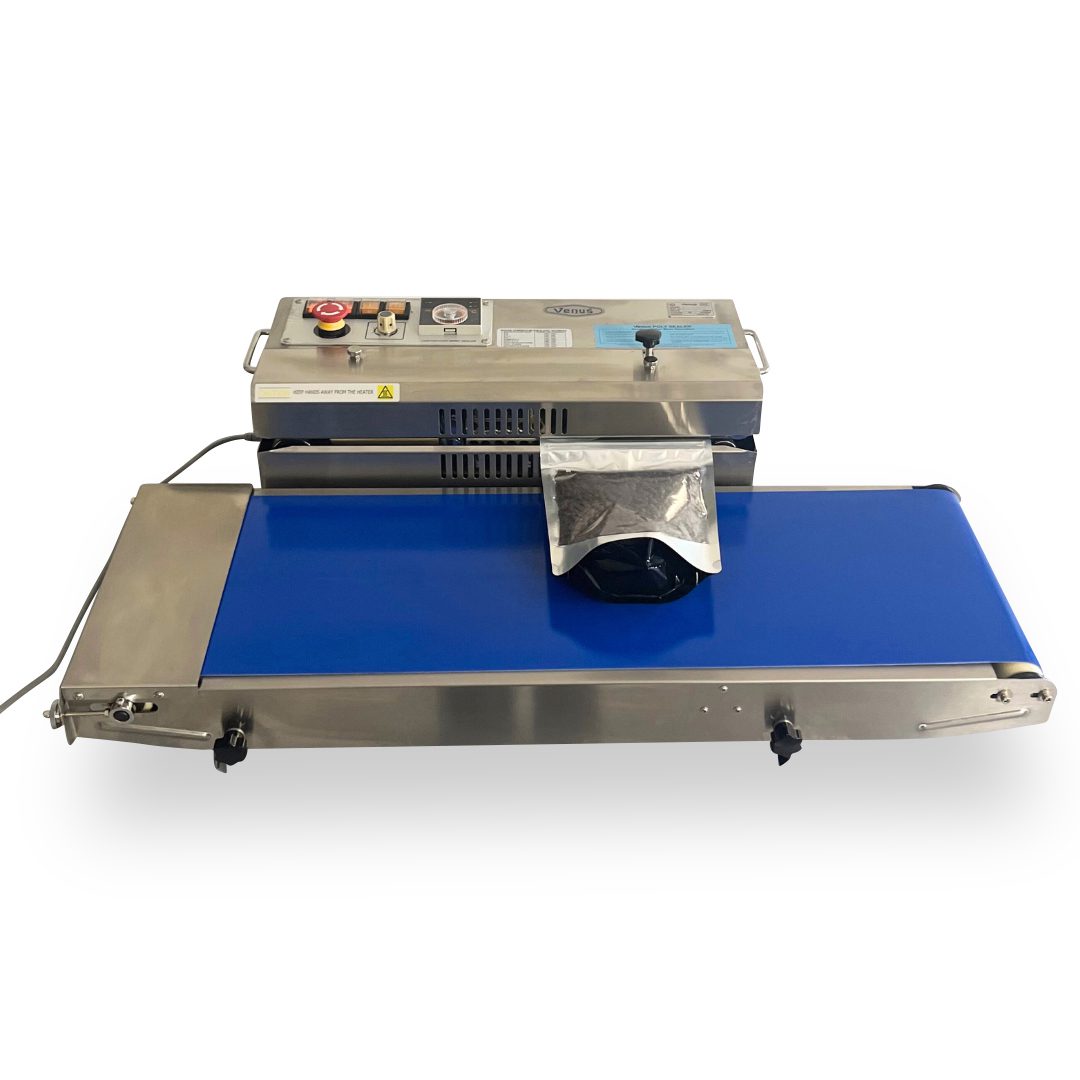

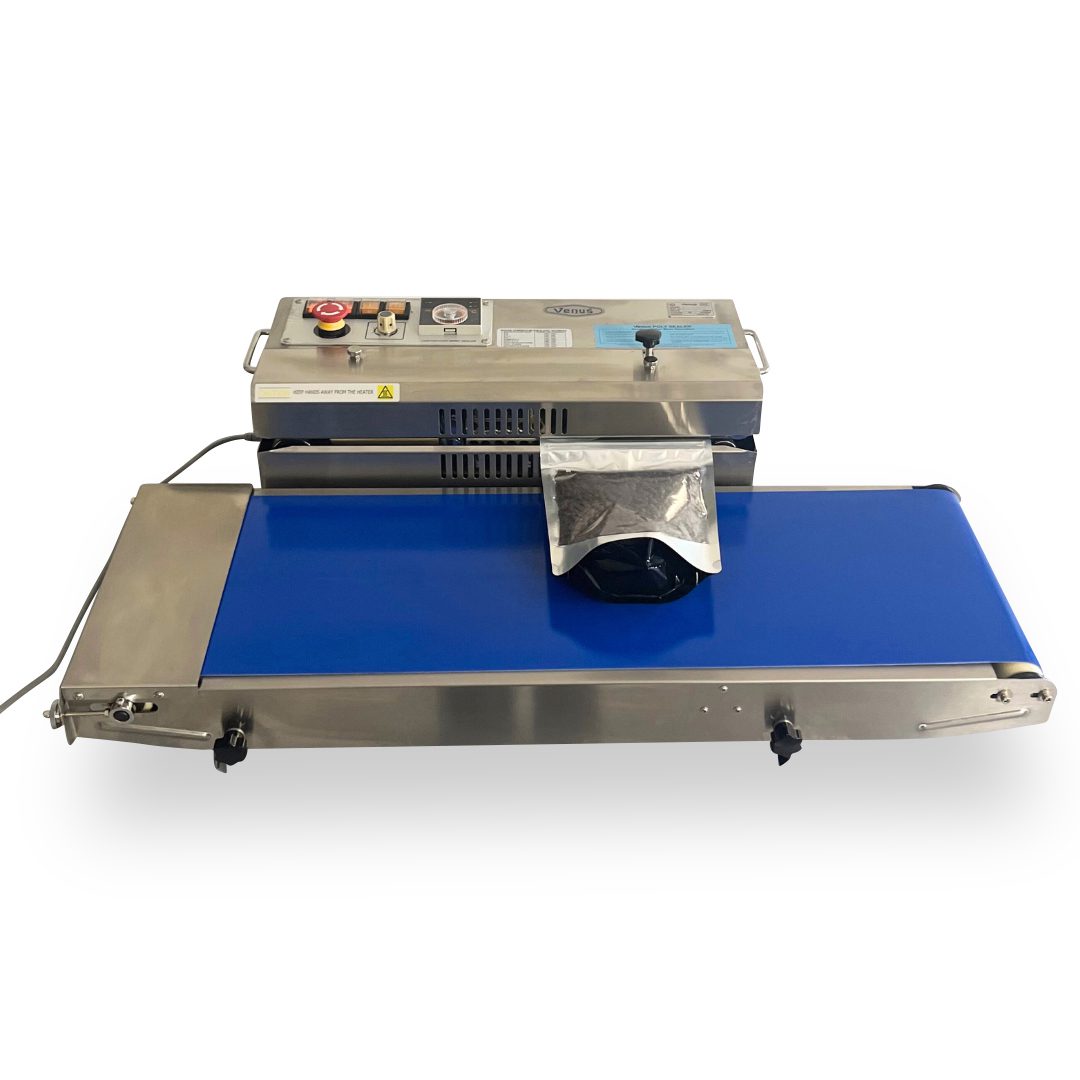

Band Sealers

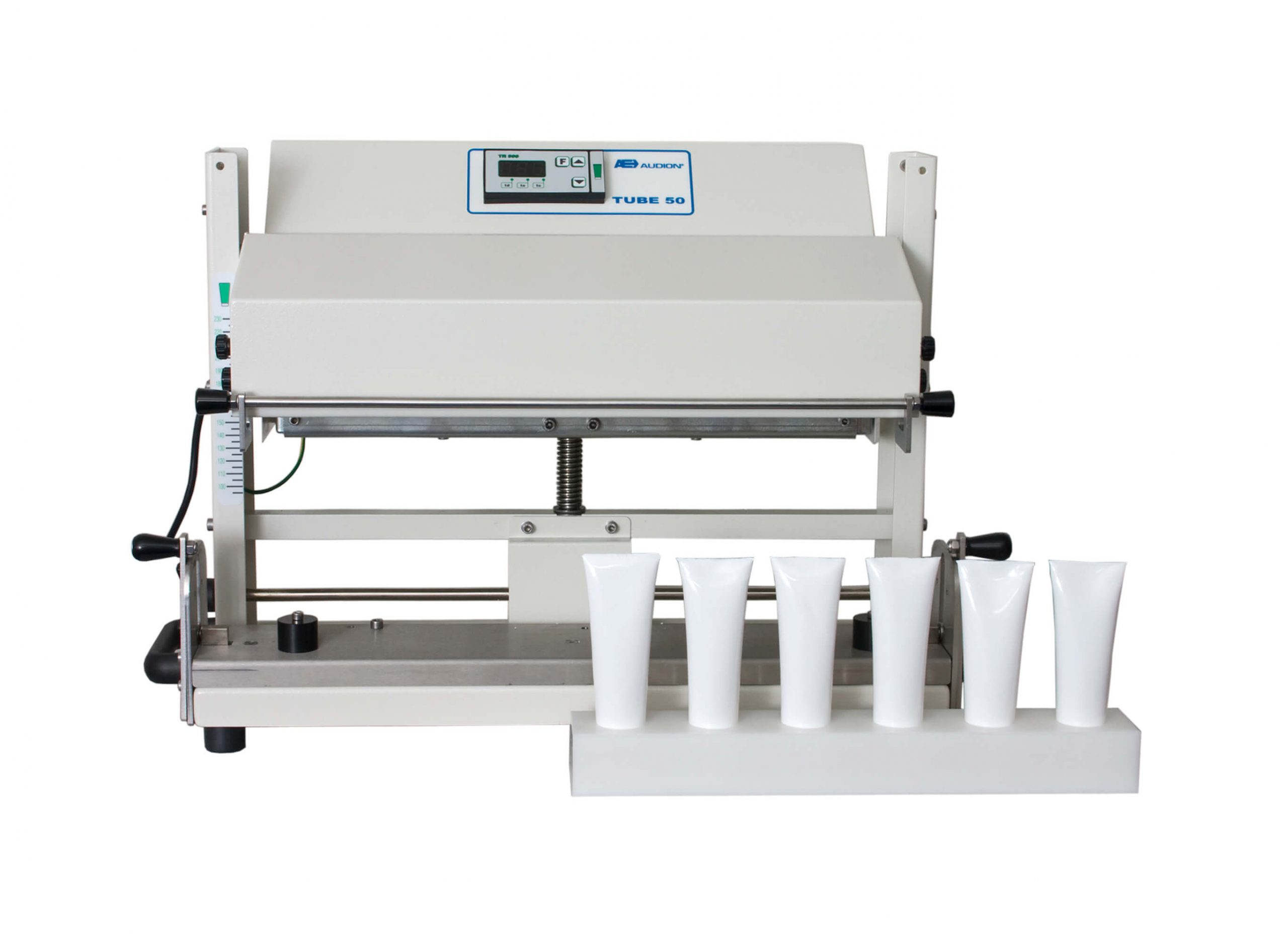

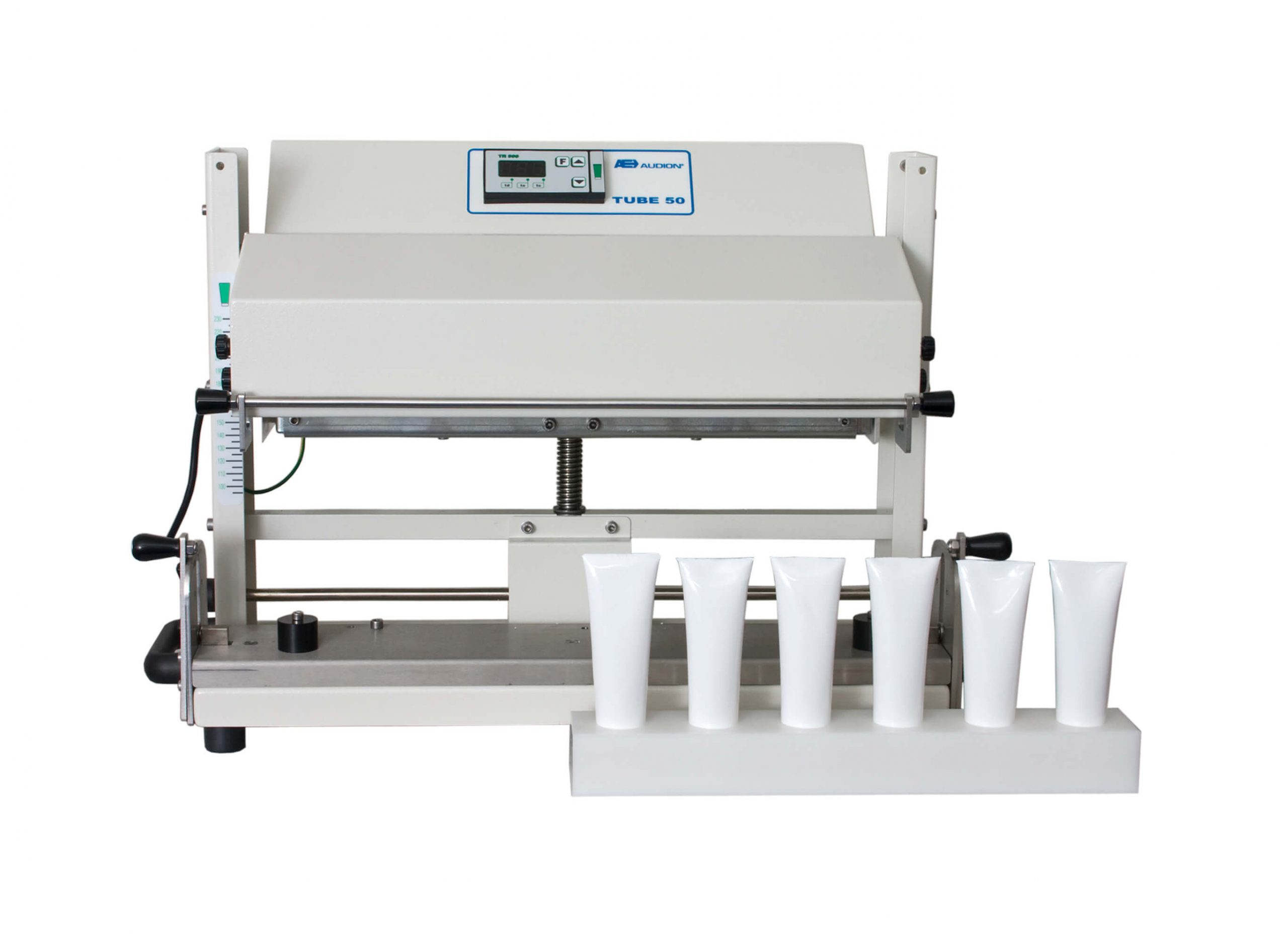

Specialty Heat Sealers

Vacuum Sealers

There are a range of different heat sealers available, and the heat sealer best suited for you will depend on your individual needs. There are constant heat sealers, band sealers, benchtop heat sealers, foot operated heat sealers, hand held heat sealers, vacuum sealers and so much more. Give our team at Venus Packaging a call at (03) 9428 1652 to help decide which heat sealer is right for your business.

Vacuum packaging extends the shelf life of any fresh perishable product by three to five times its normal refrigerated life. By removing the air that surrounds food, vacuum sealing inhibits the growth of bacteria, mould and yeast as these microorganisms need oxygen to grow. Due to this, vacuum sealing not only allows for reducing food waste but also money saving quantity buying. Food can be bought in bulk then repackaged using a vacuum sealer. Vacuum sealers also allow for more efficient use of time, as meals can be prepared in advance, frozen and sealed to be consumed at a later date without compromising on freshness.

The key difference between impulse and constant heat sealers is how they apply heat. Impulse heat sealers only heat up when the sealing arm is pressed down, using a brief burst of electricity to create the seal. This makes them ideal for sealing thin plastic materials like polyethylene and polypropylene. Constant heat sealers, on the other hand, maintain a steady temperature at the sealing jaws, which makes them better suited to thicker or multi-layered packaging materials, such as cellophane, laminated foil, or waxed paper. A constant heat seal machine is typically used for higher-volume or more heavy-duty applications.

It depends on the type of packaging material you're sealing, the volume of sealing you need to do, and whether you're looking for a manual, semi-automatic, or automatic operation. For lighter materials like polypropylene or polyethylene, an impulse heat sealer is generally sufficient. For thicker or specialty films, a constant heat seal machine or direct heat sealer may be required to ensure a consistent, reliable seal.

It's important to regularly clean the sealing bars of your heat sealer to remove any plastic residue that may build up over time. You should also inspect and replace the heating element and PTFE tape when signs of wear appear, as these components directly affect sealing quality. The silicone rubber on the upper jaw should also be checked to ensure its intact and providing even pressure.

Yes, Venus Packaging supplies a full range of spare parts for heat sealers, including heating elements, PTFE tape, and cutters. Our team also offers servicing support both over the phone and on-site, so whether you need a part replaced or a full maintenance check, our technicians are ready to assist.

The condition of the components is the first thing you should check if your heat sealer isn’t sealing properly. A worn-out heating element, damaged PTFE tape, or degraded silicone rubber can all affect the quality of the seal. It's also important to check that the sealing bars are clean. Improper positioning of the bag can cause incomplete seals as well. Addressing these issues usually resolves most sealing problems.