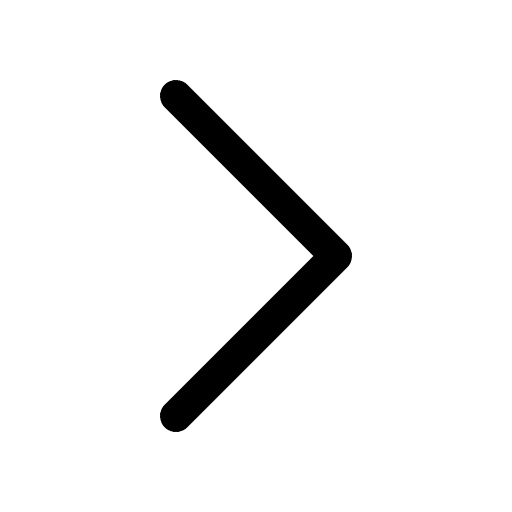

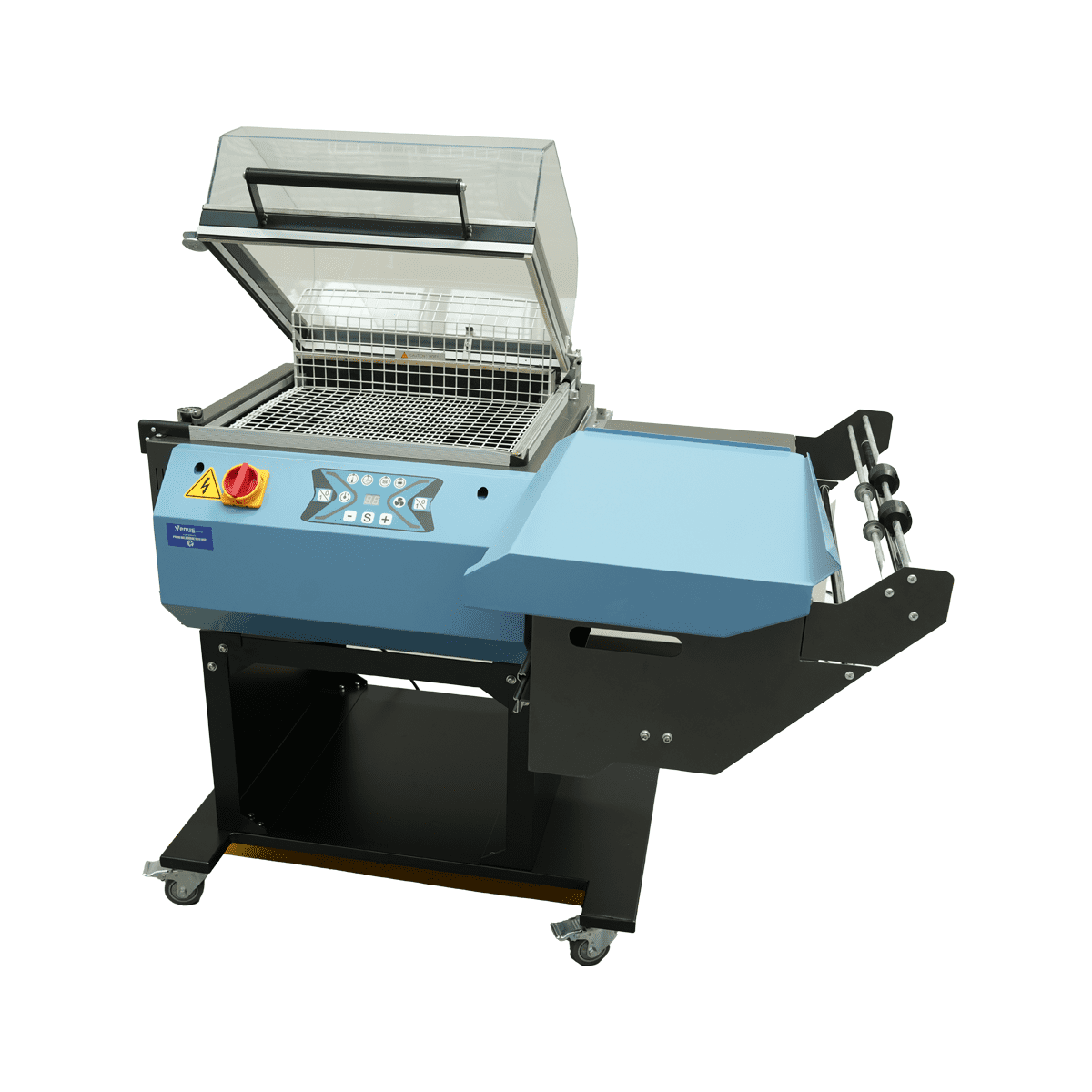

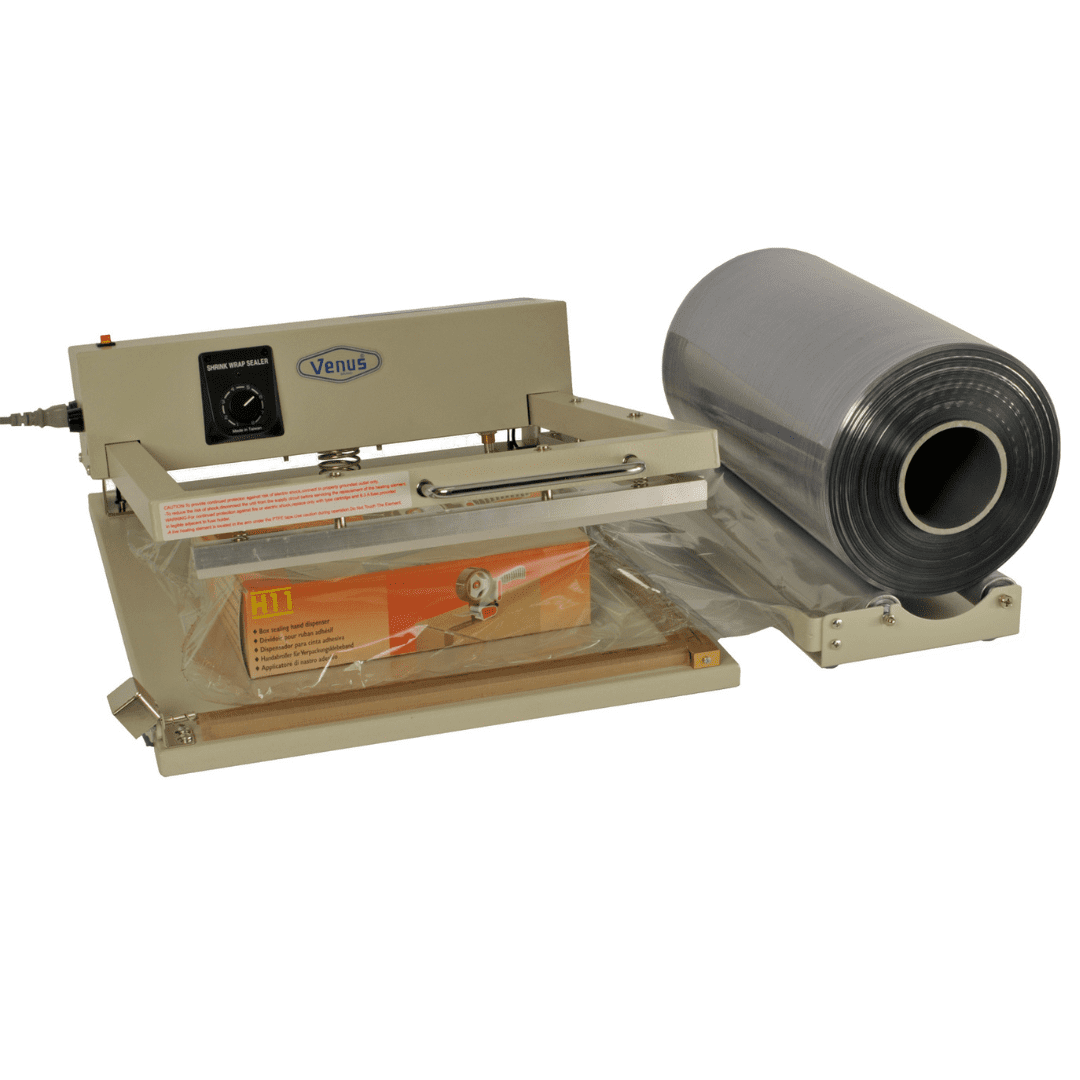

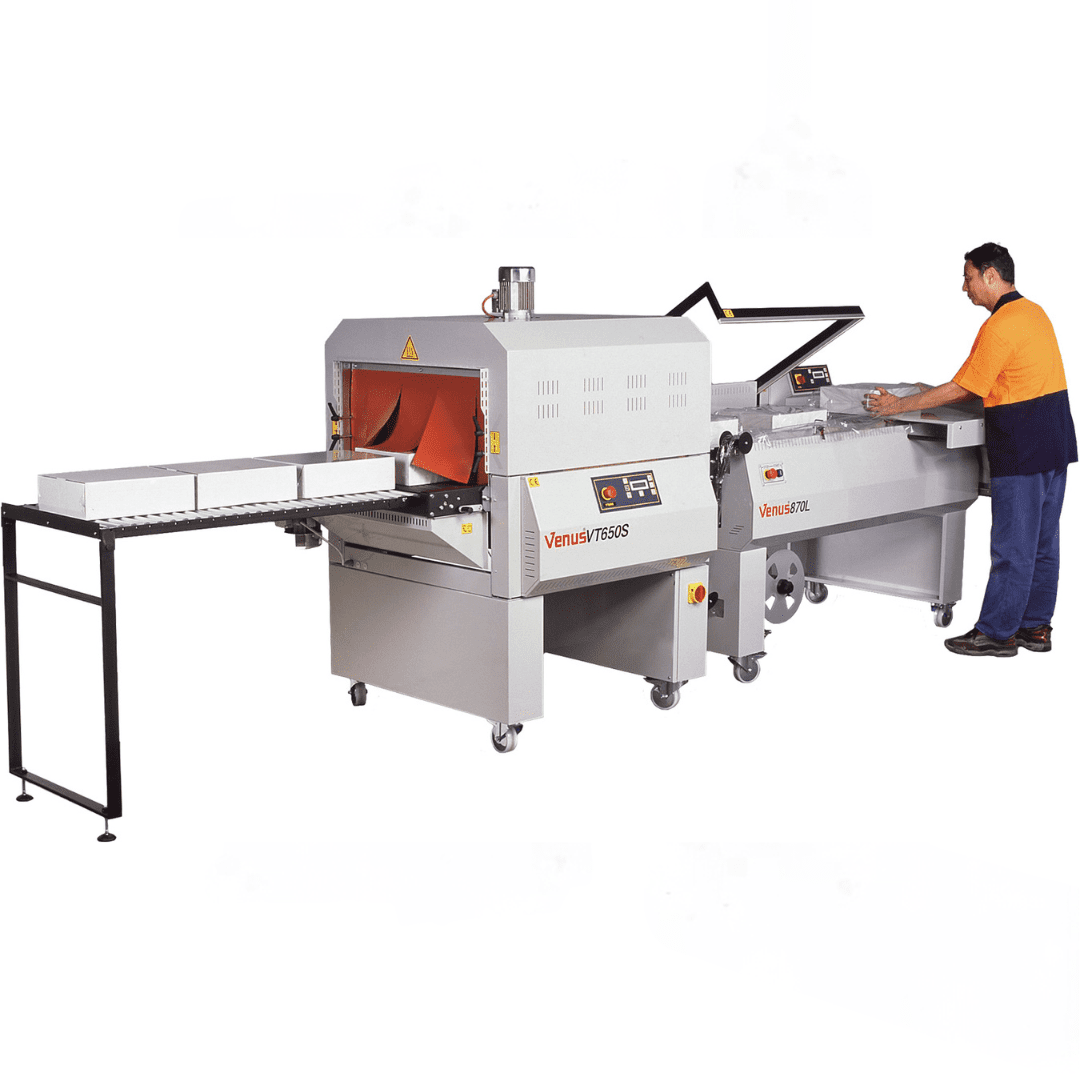

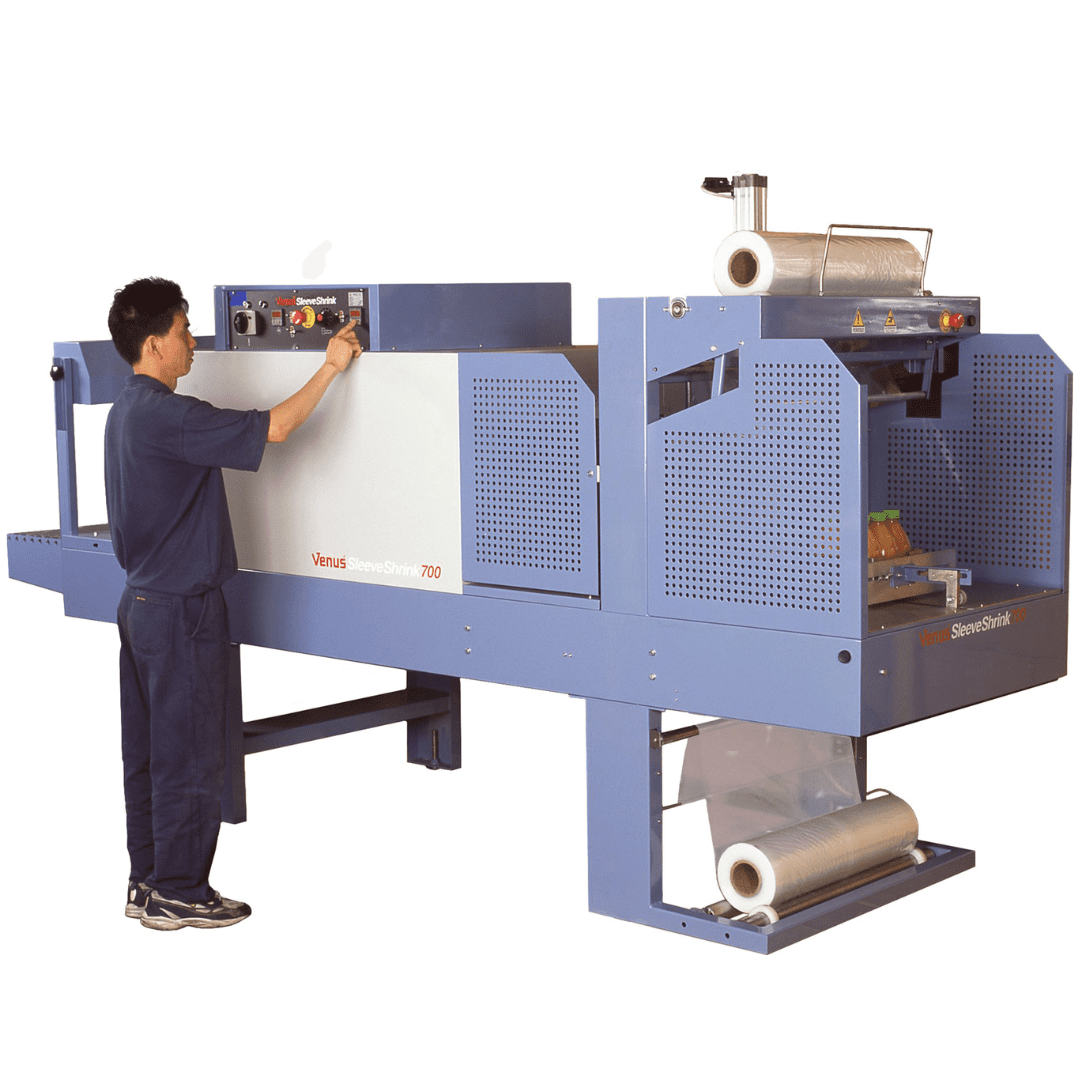

From small benchtop types to the Unishrink shrink tunnel L-bar sealer combination, we offer a broad range of L-Bar Sealers, with and without and shrink tunnels included. Most L-bar sealer models have adjustable temperature, magnetic hold down times and conveyer speeds. We also offer a range of other shrink wrap equipment.

Industry

Frequently Asked Questions

What types of products can be shrink wrapped using L-bar sealers?

Heat shrink tunnels paired with L-bar sealers are versatile and suitable for packaging a wide variety of products. They are commonly used in industries such as printing, retail, food packaging, and contract packing. Whether you’re wrapping magazines, baked goods, software boxes or hardware components, a heat shrink tunnel system offers a clean, secure, and tamper-evident solution.

What is the difference between manual and automatic shrink wrapping machines?

The main difference between manual and automatic shrink wrapping machines lies in how much of the process is automated. Manual machines require an operator to position the product and manually initiate sealing and shrink wrapping. Automatic machines handle these tasks with minimal operator involvement, often integrating an L-bar sealer with a shrink tunnel and automated conveyor.

How do I maintain and clean my L-bar sealer or shrink wrapping machine?

Regular cleaning helps prevent adhesive and film debris from building up on sealing components. Focus on cleaning the sealing bar, sealing jaws, and heating elements to ensure consistent operation. For machines that include shrink tunnels, it’s also important to inspect the conveyor belt and internal airflow system to ensure even heat distribution and reliable shrink performance.

Can L-bar sealers and shrink tunnels be customised for specific packaging needs?

Yes, both L-bar sealers and shrink tunnels can be customised to suit your specific packaging requirements. Venus Packaging offers machines with adjustable sealing areas, variable conveyor speeds, precise temperature controls, and airflow regulation within the heat shrink tunnel. These features ensure compatibility with various product sizes, shrink film types, and production speeds, making them a flexible solution for businesses with specialised needs.