Back to blog

Back to blog

Our Visit to Proud Mary Coffee

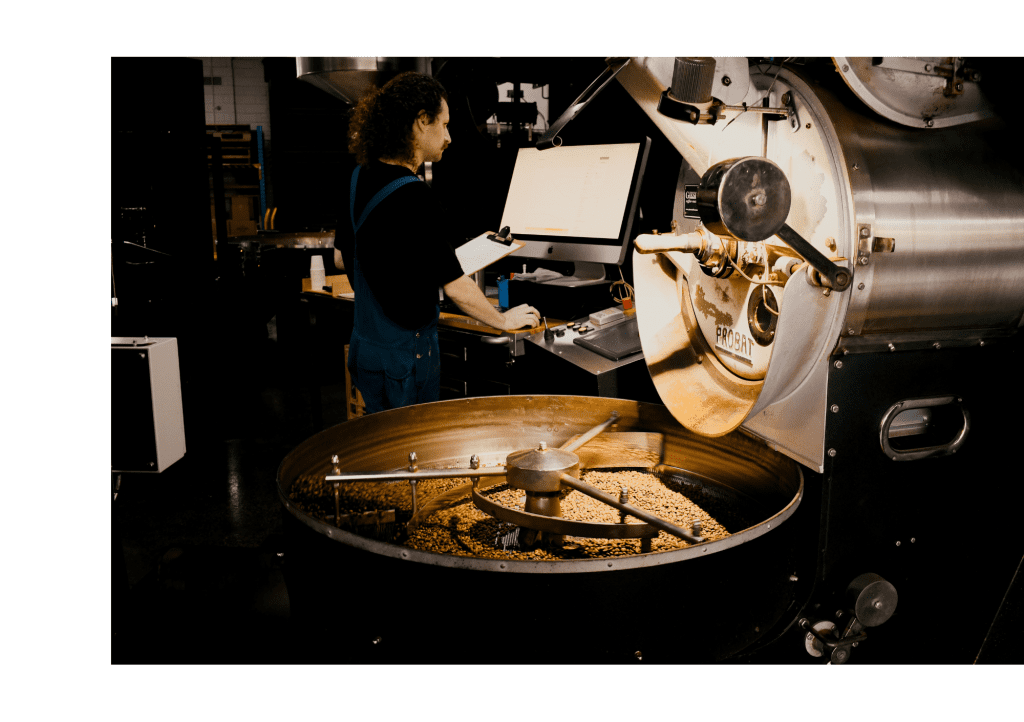

Last week, we had the opportunity to visit the operations team of Proud Mary Coffee Roasters in Collingwood to chat with them about their coffee packaging process. Proud Mary is a Melbourne-born coffee company with cafes and roasteries located in Melbourne and the US. They also supply high quality coffee to many cafes and homes across the globe.

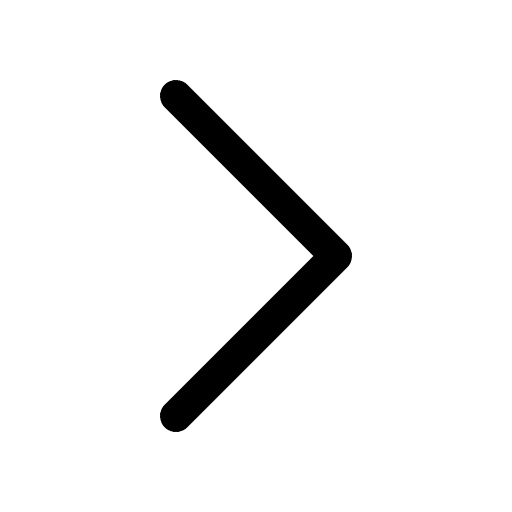

We had a tour of their roastery and their Production Manager, Alex, graciously walked us through their packaging process, offering a fascinating look into their efficient workflow. Once the coffee beans have been roasted to perfection, they’re ready to be weighed and packed into bags. Proud Mary uses the Audion All in Vertical Band Sealer to seal their coffee bags. This vertical band sealer is a free standing machine for automatically sealing upright bags. Its design offers both flexibility and durability. This band sealer comes with an adjustable conveyor belt speed and changeable height for sealing different sized bags.

Alex explained to us that originally they were using the VHS Constant Heat Sealer. This heat sealer is foot operated, and the operator seals each bag one at a time. Using the VHS heat sealer, the guys at Proud Mary could pack approximately 200 kilograms of coffee per hour. If they were really pushing it, they could pack up to 300 kilograms. Since changing to the Audion All In Vertical Band Sealer, their output has impressively increased to approximately 470 kilograms per hour, minus the physical strain on the team. This upgrade has not only greatly improved their efficiency but also contributed to a more comfortable working environment.

At Proud Mary Coffee Roasters, they’ve mastered the art of packing both 250 gram and 1 kilogram coffee bags with precision. Alex shared that in the beginning, there was a bit of trial and error involved in fine-tuning the machine settings as they initially cranked up the speed, assuming that maximum speed would translate to maximum output. However, they soon discovered the ideal conveyor belt speed and temperature that perfectly accommodates both bag sizes without compromising on packing efficiency. "Slow and consistent is the way to go," Alex says. By maintaining a lower speed and temperature, they’ve achieved a seamless transition between bag sizes without the need for constant adjustments. "And now, the machine basically looks after itself," Alex added. The Proud Mary team hasn’t had to reach out to the Venus Service Team for any maintenance, as their band sealer has been running smoothly without any technical hiccups.

We were fortunate to leave with a bag of Proud Mary Coffee, which our Venus Packaging team are now enjoying in our office. A heartfelt thank you to Alex and the entire Proud Mary team for their hospitality and for giving us an inside look into their world of exceptional coffee (and packaging). It’s clear that their dedication to quality and efficiency is what sets them apart. Until next time, we’ll be savouring every sip of their expertly made and meticulously packed coffee.