Back to blog

Back to blog

Shrink Packaging

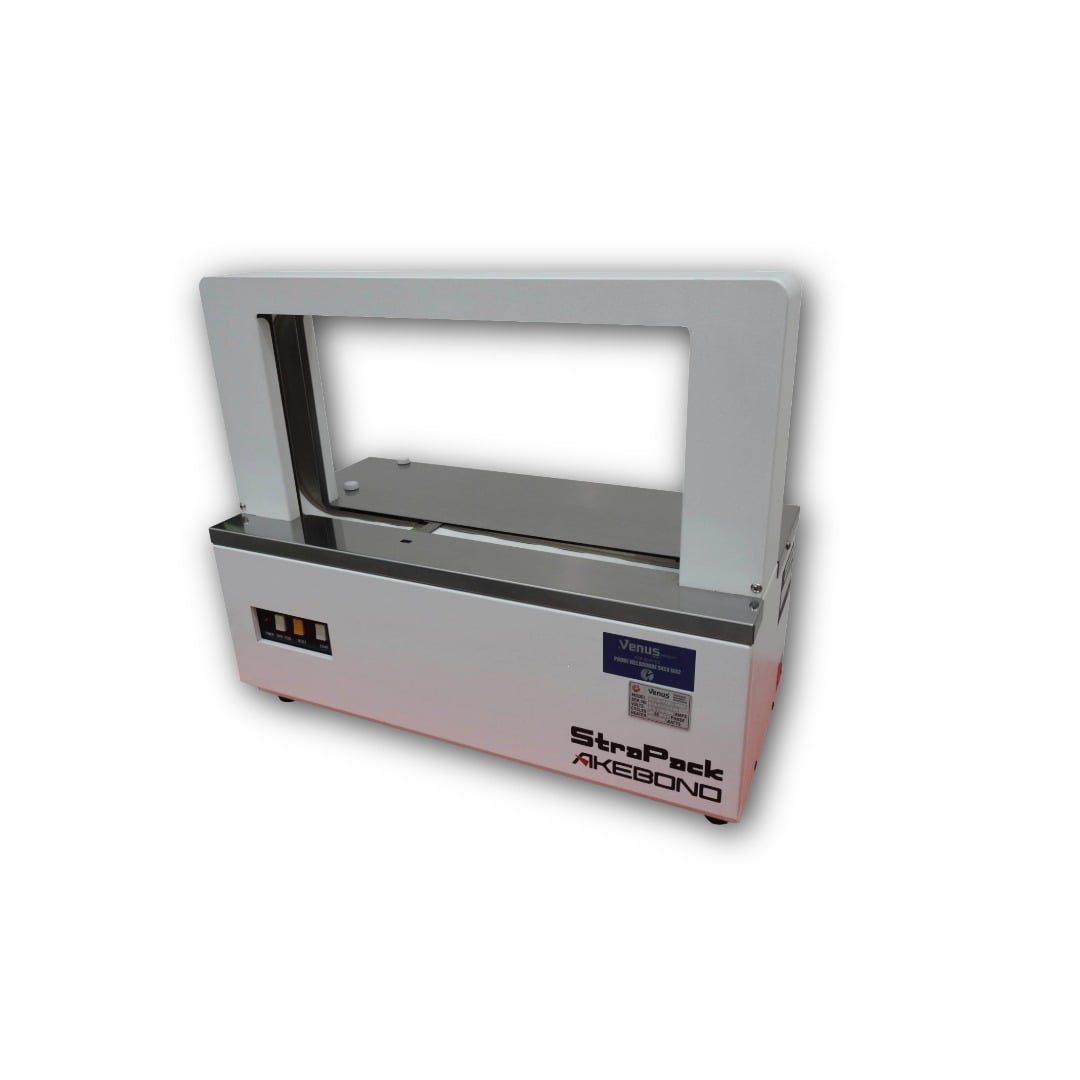

Shrink packaging, or shrink wrapping, as it is commonly known, has long provided a professional and effective method of packaging everything from food products to children’s toys. Put simply, the process of shrink wrapping works with a plastic film placed around the product and then exposed to fan forced heat. In this environment the film reacts to mould or ‘shrink’ around the product.

The good news is that with the Venus Shrink-A-Pack System, this kind of professional finish and tamper evident packaging is accessible to all. This cost-effective machine is simple, easy to use and will wrap your product ready for the shelf or dispatch within a minute.

Once your business grows, take the next step up in output with the Audion Pack UniH25. The Pack UniH25 is great for medium sized productions of up to 300 packs per hour. The hood is closed by an electronic hold-down magnet during the film sealing and automatically opens after the completion of the cycle. The Pack UniH25 can be used with PE, PVC and Polyolefin films.

If high output is the need, we can offer a range of L-Bar sealers and shrink tunnel combinations. Starting with the Venus 560 L Bar Sealer, paired with the Venus VT450 Shrink Tunnel, higher product throughput can be achieved. The units can be switched to auto mode so that the operator is just loading the items to be packed. Bigger auto feed units are also available.

Discover our full range of shrink wrapping equipment here or get in contact with our knowledgeable sales team on (03) 9428 1652 or email sales@venuspack.com.au