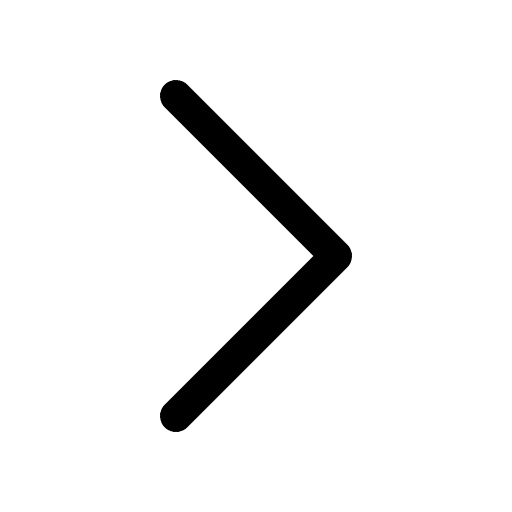

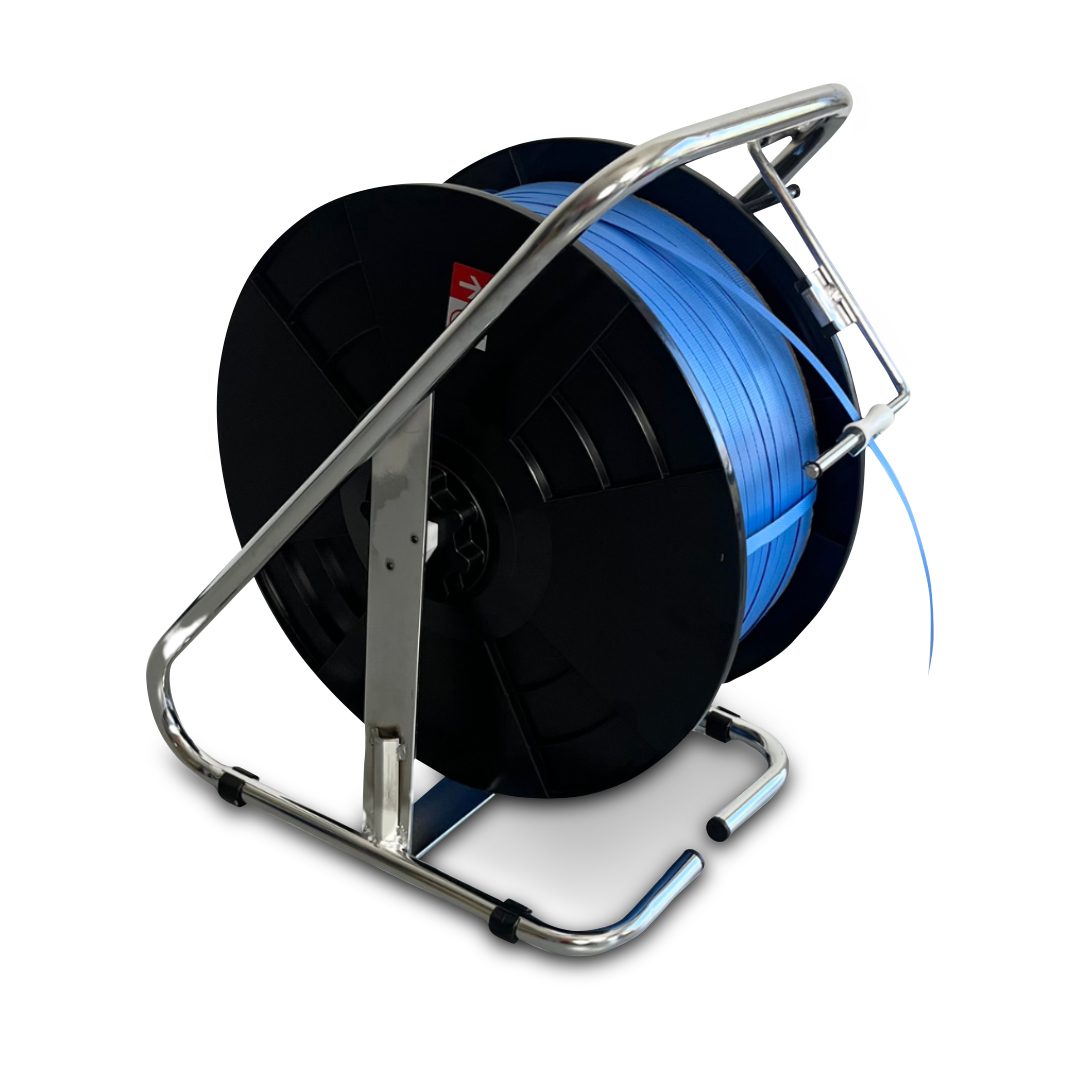

A complete range of poly strapping tools, including PP strapping tensioners and crimpers, designed for ease of use and efficiency. We also offer a selection of combination plastic strapping tools that allow for both tensioning and crimping in one convenient device. For easy dispensing, our plastic strapping dispenser range includes models suitable for various operational needs. Tools are available to suit 12mm, 16mm, and 19mm PP strapping.

Frequently Asked Questions

Can PP strapping dispensers be used with all roll sizes?

No, PP strapping dispensers are not universally compatible with all roll sizes. They are typically designed for specific core sizes, coil diameters, and strap widths. Before selecting a dispenser, it’s important to confirm the dimensions of your plastic strap roll to ensure proper fit and function. Using the wrong dispenser can lead to poor performance, wasted material, or even damage to the strapping.

How do I choose the right hand tool for PP strapping?

Choosing the right hand tool for PP strapping depends on several factors, including the width and thickness of the strap, how often the tool will be used, and the working environment. For low to medium-volume packaging tasks, a manual tensioner and sealer are often sufficient. For more frequent use, a combination tool may improve efficiency.

Are your PP strapping tools suitable for heavy-duty applications?

Venus Packaging offers a wide selection of strapping tools designed for various applications. While pp strapping tools are well-suited for securing light to medium loads such as cartons or small pallets, they may not be suitable for very heavy or high-tension jobs. In those cases, steel strapping and corresponding steel tools would be the better option. The key is to match the tool and strap type with the demands of your load.

Do I need special training to use PP strapping hand tools and dispensers?

No, special training is not required to use PP strapping hand tools, however basic training is recommended, especially for new users or those handling higher volumes. Understanding how to properly tension, seal, and cut the plastic strap not only ensures a secure result but also improves safety and efficiency in the workplace.