Back to blog

Back to blog

Choose The Right Strapping And Strapping Dispenser For Your Business

Our strapping, strapping machines and strapping hand tools are among some of our most popular products. Here are some key points to consider if you are introducing strap packaging to your business or upgrading to an automated strapping machine…

What strapping should I use?

Steel Strapping is the strongest strapping and is used for the most demanding heavy-duty applications particularly in the manufacturing and construction industries.

- Available in standard ‘blued’ steel, black painted steel & stainless steel

- Provides high strength and minimal stretch

- Used for locking items into place such as machinery atop a pallet

- Commonly used in binding together manufactured items such as pallets of bricks, metal piping and other construction materials

- General use in handling and shipping to ensure safe passage and untampered delivery

- Securing steel strapping is straightforward using Venhart Steel Strapping Tools. First, place the strapping around the product, tension the strapping with a Venhart Tensioner and join the strapping using steel buckles and a crimper. Then cut with shears

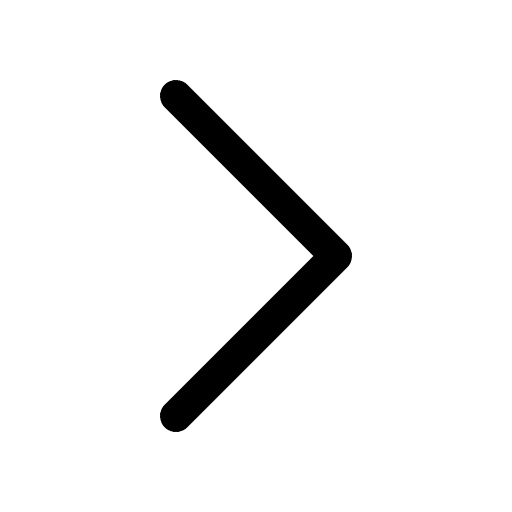

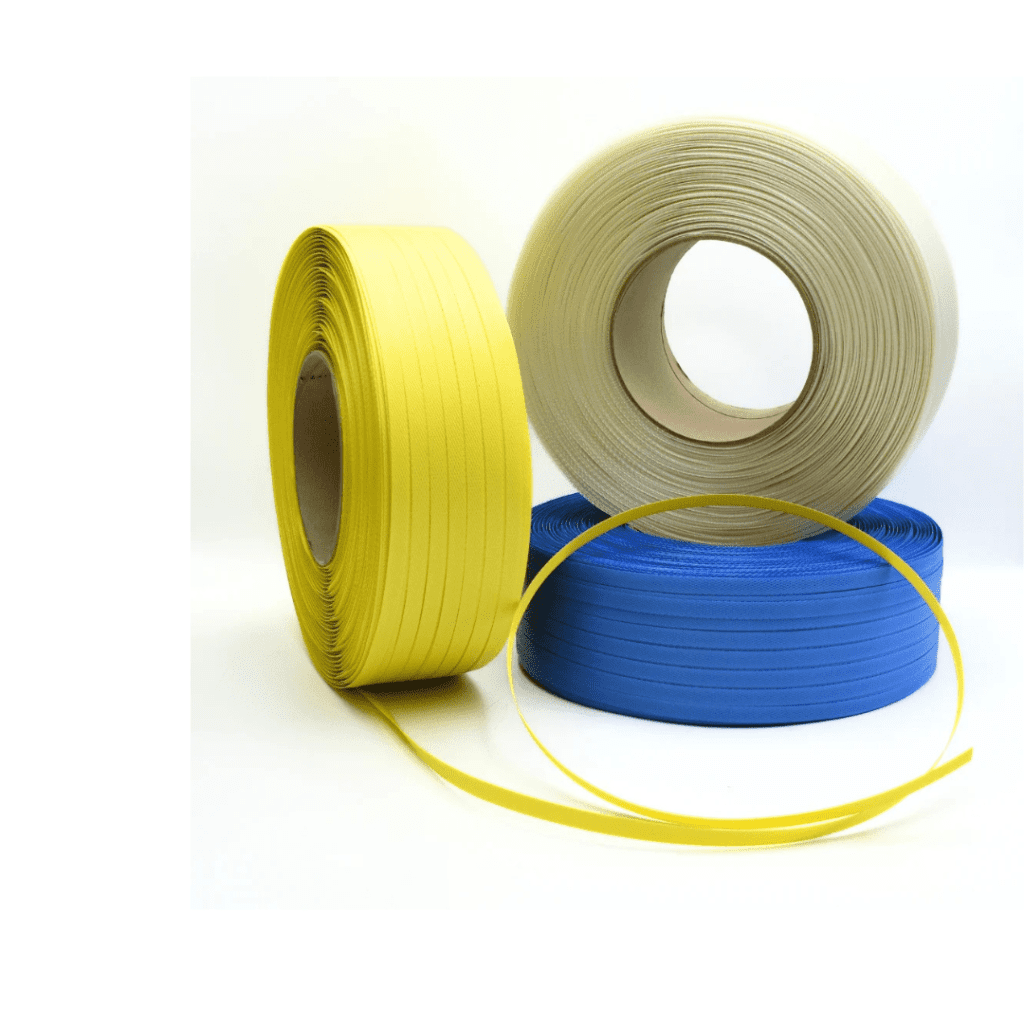

Although steel strapping plays an important role in securing extremely heavy loads, Plastic strapping - polyester & polypropylene (PP) strapping have some benefits over steel strapping:

- Higher strap tension can be achieved

- Lower cost strapping

- Cheaper to ship as lighter in weight

- Safer to use, as steel strapping can create cutting hazards

- No chance of rust/corrosion and can be used on boxes that may be refrigerated or frozen

- Easier to manage and store as lighter weight

- Easier handling and disposal after use

How do I apply plastic strapping to my products/shipping?

There are several options to seal/join plastic strapping:

Semi-automatic Strapping Machines & Automatic Strapping Machines

- The next level up from strapping hand tools. Strapping machines allow automation of strapping procedures.

- Semi-automatic strapping machines use longer rolls of PP strapping that are mounted to the machine, and require the operator to wrap the strap around the parcel and then the machine does the rest.

- Automatic strapping machines simply require the operator to place the carton or parcel under the arch of the strapping machine and with the press of a button, or foot pedal, the machine applies the strapping and heat seals and cuts the strapping.

- Strapping machines ensure minimal, if any, waste of strapping as they are designed to use the exact amount of strapping required.

- Manual, low-cost hand tools to cut the strapping and seal the ends around a pallet or carton.

- Venhart Strapping Tools include shears, tensioners & crimpers.

- These tools are used in conjunction with plastic or steel buckles & seals.

- Strapping Power Tools are a more versatile option, particularly good for larger, odd shaped objects that cannot be put through a strapping machine.

- These are hand-held, easy to use machines that tension, and then friction-seal strapping around a carton, product or pallet.

- Consistent tension and seal quality

- Great for reducing operator fatigue compared to manual strapping methods

Strapping tools & machines can be serviced or repaired by the Venus Service Team.

All strapping machines from Venus come with a 12 month warranty.

Advice on the best strapping tool or strapping machine for your business can be sought from us at Venus Packaging.

Call us at (03) 9428-1652 or email for advice venus@venuspacking.com.au